1Confidential Information. Do Not Distribute. 1 Confidential Information. Do Not Distribute. Fourth Quarter 2023 Corporate Update March 6, 2024 Exhibit 99.2

2Confidential Information. Do Not Distribute. 2 Forward-Looking Statements Certain statements in this Presentation contain forward-looking statements within the meaning of Section 27A of the Securities Act of 1933, as amended (the “Securities Act”), and Section 21E of the Securities Exchange Act of 1934, as amended (the “Exchange Act”), including statements about the financial condition, results of operations, earnings outlook and prospects of PureCycle Technologies, Inc. (“PCT”). Forward-looking statements generally relate to future events or our future financial or operating performance and may refer to projections and forecasts. Forward-looking statements are typically identified by words such as “plan,” “believe,” “expect,” “anticipate,” “intend,” “outlook,” “estimate,” “forecast,” “project,” “continue,” “could,” “may,” “might,” “possible,” “potential,” “predict,” “should,” “would” and other similar words and expressions (or the negative versions of such words or expressions), but the absence of these words does not mean that a statement is not forward-looking. The forward-looking statements are based on the current expectations of PureCycle’s management and are inherently subject to uncertainties and changes in circumstances and their potential effects and speak only as of the date of this press release. There can be no assurance that future developments will be those that have been anticipated. These forward-looking statements involve a number of risks, uncertainties or other assumptions that may cause actual results or performance to be materially different from those expressed or implied by these forward-looking statements. These risks and uncertainties include, but are not limited to, those factors described in the section entitled “Risk Factors” in each of PureCycle’s Annual Report on Form 10-K for the fiscal year ended December 31, 2023 and PureCycle’s Quarterly Reports on Form 10-Q, those discussed and identified in other public filings made with the Securities and Exchange Commission by PureCycle and the following: PCT's ability to obtain funding for its operations and future growth and to continue as a going concern; PCT's ability to meet, and to continue to meet, applicable regulatory requirements for the use of PCT’s ultra-pure recycled (“UPR”) resin in food grade applications (including in the United States, Europe, Asia and other future international locations); PCT's ability to comply on an ongoing basis with the numerous regulatory requirements applicable to the UPR resin and PCT’s facilities (including in the United States, Europe, Asia and other future international locations); expectations and changes regarding PCT’s strategies and future financial performance, including its future business plans, expansion plans or objectives, prospective performance and opportunities and competitors, revenues, products and services, pricing, operating expenses, market trends, liquidity, cash flows and uses of cash, capital expenditures, and PCT’s ability to invest in growth initiatives; the ability of PCT’s first commercial-scale recycling facility in Lawrence County, Ohio (the “Ironton Facility”) to be appropriately certified by Leidos, following certain performance and other tests, and commence full-scale commercial operations in a timely and cost-effective manner or at all; PCT’s ability to meet, and to continue to meet, the requirements imposed upon it and its subsidiaries by the funding for its operations, including the funding for the Ironton Facility; PCT’s ability to minimize or eliminate the many hazards and operational risks at its manufacturing facilities that can result in potential injury to individuals, disrupt its business (including interruptions or disruptions in operations at its facilities), and subject PCT to liability and increased costs; PCT’s ability to complete the necessary funding with respect to, and complete the construction of, (i) its first U.S. multi-line facility, located in Augusta, Georgia; (ii) its first commercial-scale European plant located in Antwerp, Belgium and (iii) its first commercial-scale Asian plant located in Ulsan, South Korea, in a timely and cost-effective manner; PCT’s ability to establish, sort and process polypropylene plastic waste at its plastic waste prep facilities; PCT’s ability to maintain exclusivity under the Procter & Gamble Company license; the implementation, market acceptance and success of PCT’s business model and growth strategy; the success or profitability of PCT’s offtake arrangements; the ability to source feedstock with a high polypropylene content at a reasonable cost; PCT’s future capital requirements and sources and uses of cash; developments and projections relating to PCT’s competitors and industry; the outcome of any legal or regulatory proceedings to which PCT is, or may become, a party including the securities class action and putative class action cases; geopolitical risk and changes in applicable laws or regulations; the possibility that PCT may be adversely affected by other economic, business, and/or competitive factors, including rising interest rates, availability of capital, economic cycles, and other macro-economic impacts; turnover in employees and increases in employee-related costs; changes in the prices and availability of labor (including labor shortages), transportation and materials, including inflation, supply chain conditions and its related impact on energy and raw materials, and PCT’s ability to obtain them in a timely and cost-effective manner; any business disruptions due to political or economic instability, pandemics, armed hostilities (including the ongoing conflict between Russia and Ukraine and the current conflict in the Middle East); the potential impact of climate change on PCT, including physical and transition risks, higher regulatory and compliance costs, reputational risks, and availability of capital on attractive terms; and operational risk. Should one or more of these risks or uncertainties materialize or should any of the assumptions made by the management of PCT prove incorrect, actual results may vary in material respects from those projected in these forward-looking statements. All subsequent written and oral forward-looking statements or other matters attributable to PCT or any person acting on their behalf are expressly qualified in their entirety by the cautionary statements contained or referred to in this Presentation. Except to the extent required by applicable law or regulation, PCT undertakes no obligation to update these forward-looking statements to reflect events or circumstances after the date of this Presentation or to reflect the occurrence of unanticipated events.

3Confidential Information. Do Not Distribute. 3 Jaime Vasquez Chief Financial Officer • More than 20 years experience as financial executive • Extensive experience with manufacturing & publicly traded companies • Previously Chief Financial Officer at C&D Technologies & AK Steel PureCycle’s New CFO Overview Ironton Growth Finance

4Confidential Information. Do Not Distribute. 4 Ironton’s Operations are Gaining Momentum Overview Ironton Growth Finance Manufacturing • Achieved 8,000 lbs. per hour end-to-end production. • Successfully ran 100% PCR feed with a range of feed types • Rates are limited by co- product 2 (CP2) removal • Utilities per unit consumption is significantly lower than design Commercial • First revenue achieved • Product color/opacity has been impacted by reliability challenges • Product development underway for numerous product applications • Strong demand for all production grades End-to-end operations reached ~60% of benchmark rates Next Steps • Scheduled outage in early Q2 • Q2 improvements should improve reliability, product quality, and co-product 2 removal • Optimizing feedstock purchasing plan to minimize short-term co-product 2 limitation

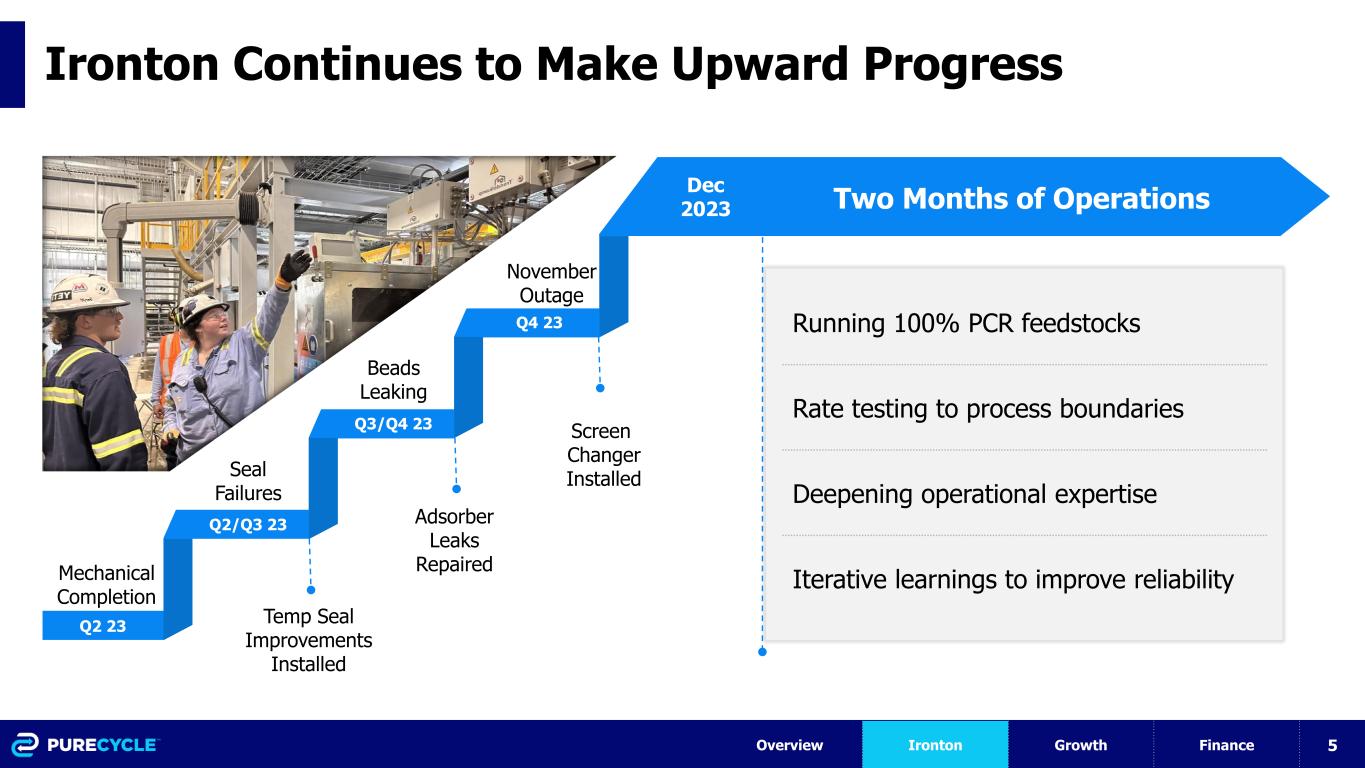

5Confidential Information. Do Not Distribute. 5 Ironton Continues to Make Upward Progress Mechanical Completion Seal Failures Beads Leaking November Outage Q2 23 Q2/Q3 23 Q3/Q4 23 Q4 23 Dec 2023 Running 100% PCR feedstocks Rate testing to process boundaries Deepening operational expertise Iterative learnings to improve reliability Two Months of Operations Overview Ironton Growth Finance Screen Changer Installed Temp Seal Improvements Installed Adsorber Leaks Repaired

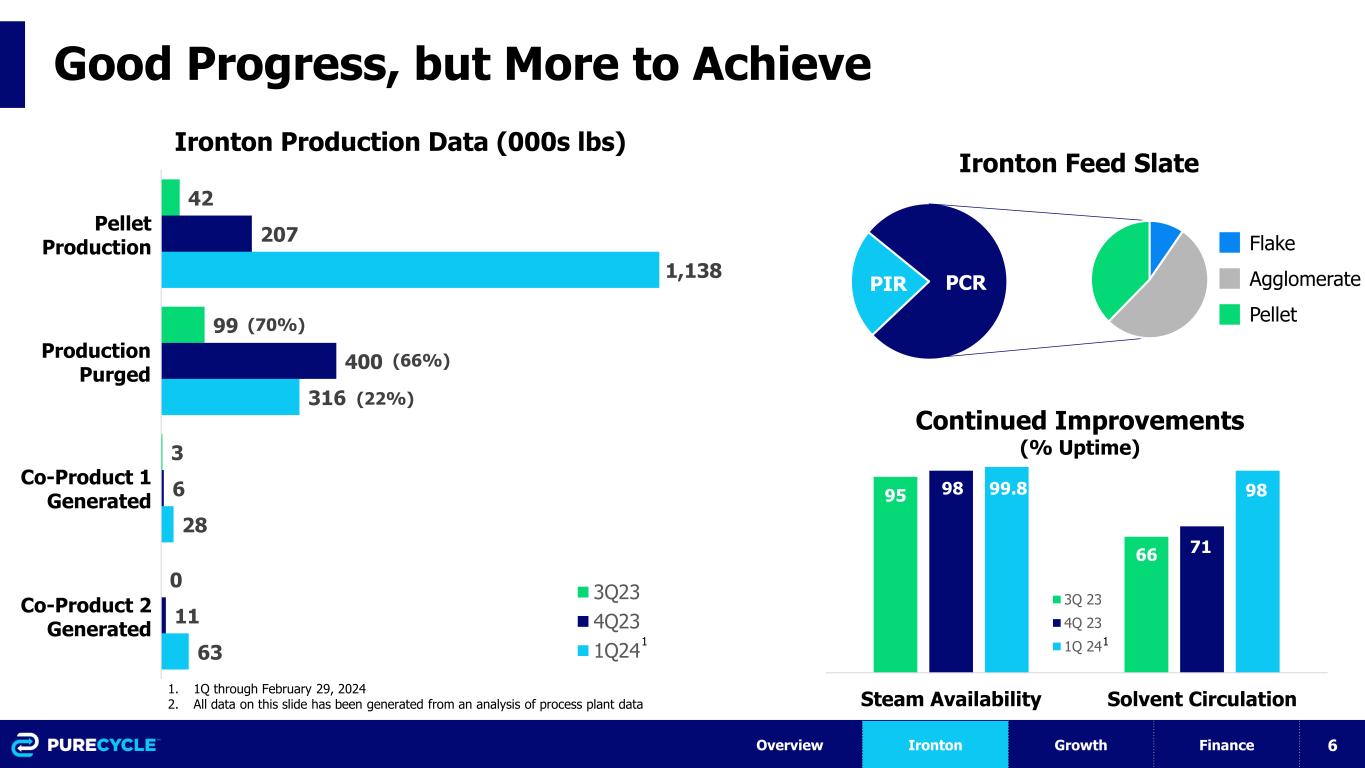

6Confidential Information. Do Not Distribute. 6 Good Progress, but More to Achieve Ironton Feed Slate Continued Improvements (% Uptime) PCRPIR Flake Agglomerate Pellet 95 66 98 71 99.8 98 Steam Availability Solvent Circulation 3Q 23 4Q 23 1Q 24 42 99 3 0 207 400 6 11 1,138 316 28 63 3Q23 4Q23 1Q24 Pellet Production Ironton Production Data (000s lbs) 1 1. 1Q through February 29, 2024 2. All data on this slide has been generated from an analysis of process plant data Co-Product 1 Generated Co-Product 2 Generated Production Purged Overview Ironton Growth Finance (70%) (22%) (66%) 1

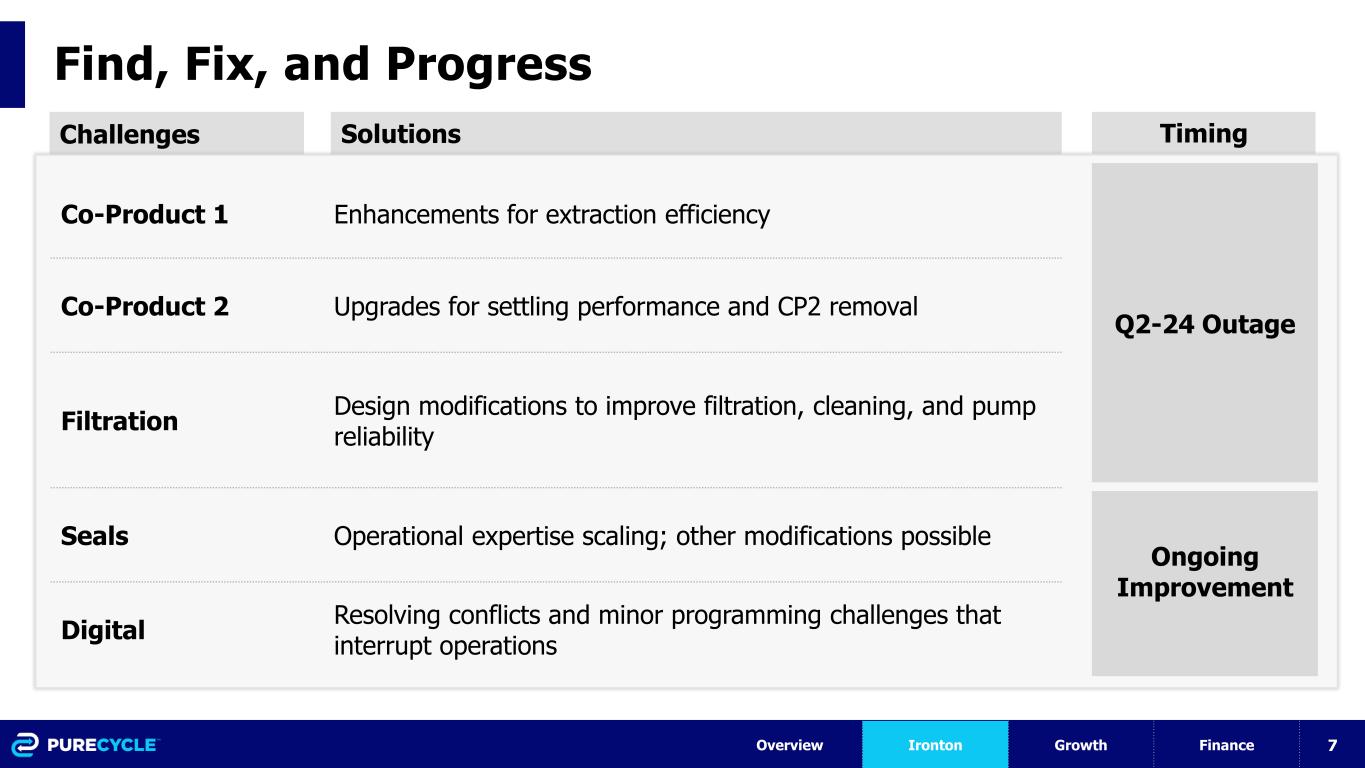

7Confidential Information. Do Not Distribute. 7 Timing Find, Fix, and Progress Overview Ironton Growth Finance Co-Product 1 Enhancements for extraction efficiency Co-Product 2 Upgrades for settling performance and CP2 removal Filtration Design modifications to improve filtration, cleaning, and pump reliability Seals Operational expertise scaling; other modifications possible Digital Resolving conflicts and minor programming challenges that interrupt operations Challenges Ongoing Improvement Q2-24 Outage Solutions

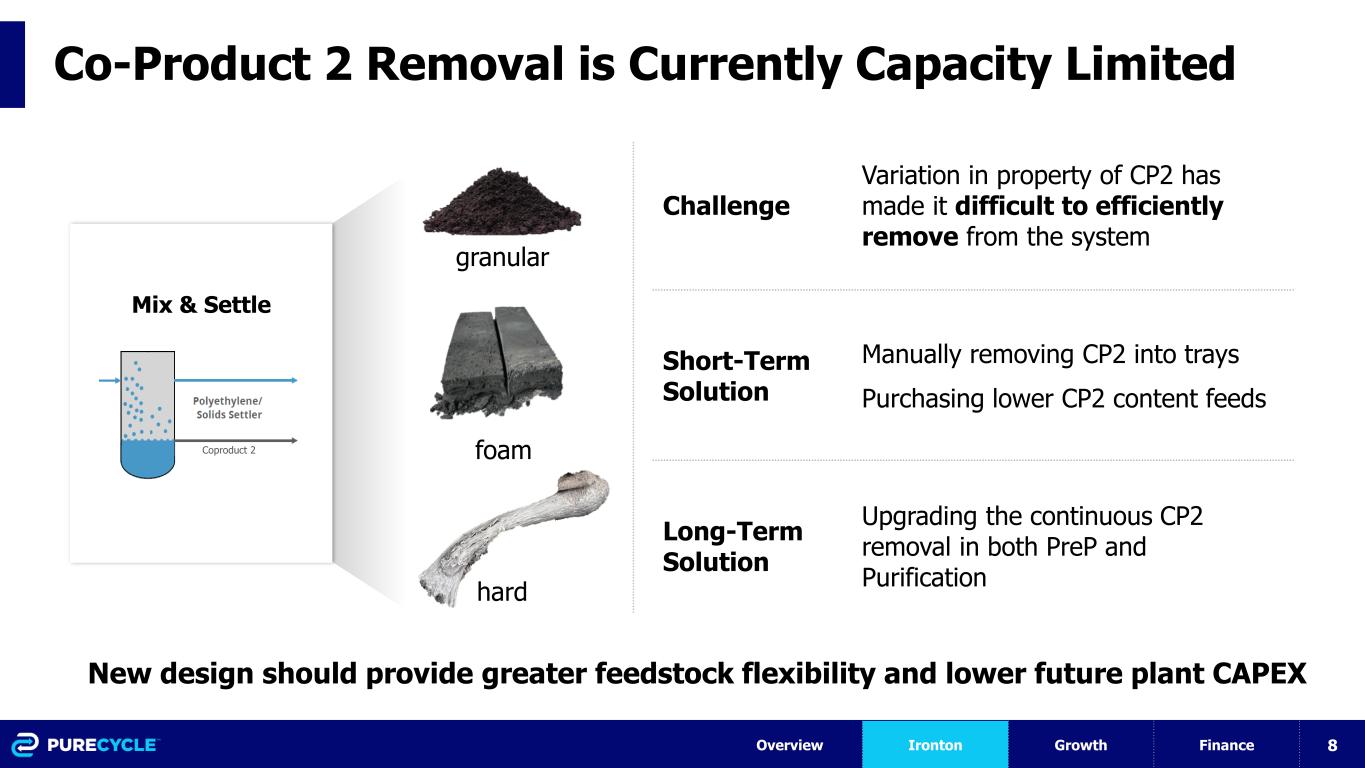

8Confidential Information. Do Not Distribute. 8 Co-Product 2 Removal is Currently Capacity Limited Mix & Settle granular hard foam Challenge Variation in property of CP2 has made it difficult to efficiently remove from the system Short-Term Solution Manually removing CP2 into trays Purchasing lower CP2 content feeds Long-Term Solution Upgrading the continuous CP2 removal in both PreP and Purification Coproduct 2 New design should provide greater feedstock flexibility and lower future plant CAPEX Overview Ironton Growth Finance

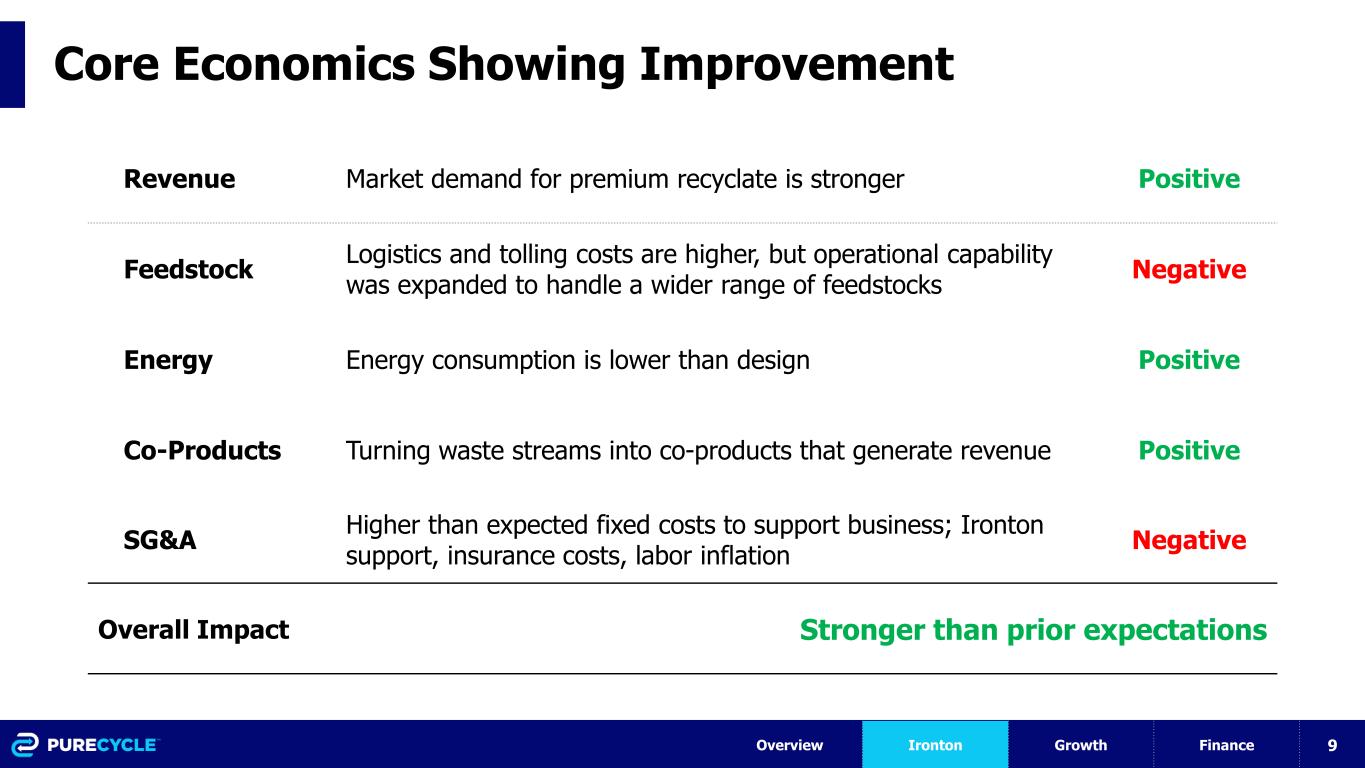

9Confidential Information. Do Not Distribute. 9 Revenue Market demand for premium recyclate is stronger Positive Feedstock Logistics and tolling costs are higher, but operational capability was expanded to handle a wider range of feedstocks Negative Energy Energy consumption is lower than design Positive Co-Products Turning waste streams into co-products that generate revenue Positive SG&A Higher than expected fixed costs to support business; Ironton support, insurance costs, labor inflation Negative Overall Impact Stronger than prior expectations Core Economics Showing Improvement Overview Ironton Growth Finance

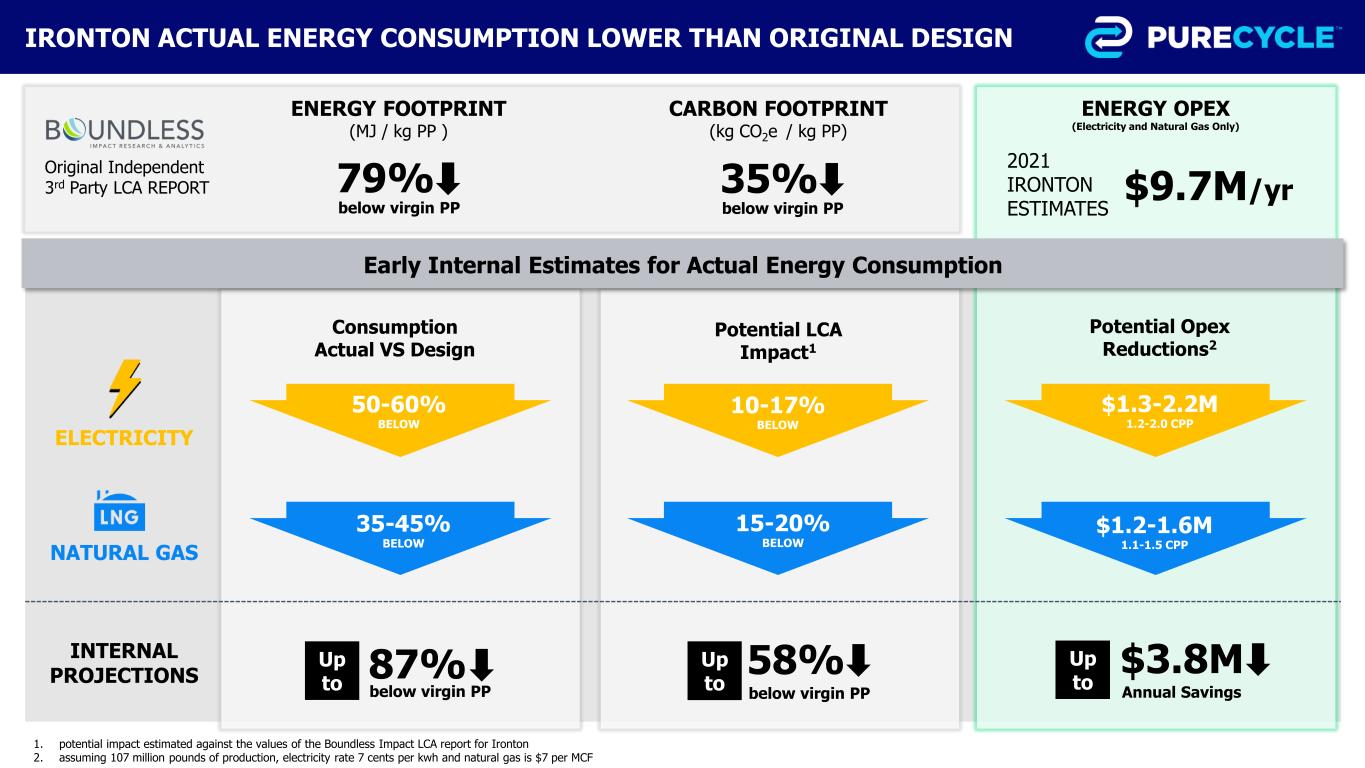

10Confidential Information. Do Not Distribute. ENERGY FOOTPRINT (MJ / kg PP ) CARBON FOOTPRINT (kg CO2e / kg PP) IRONTON ACTUAL ENERGY CONSUMPTION LOWER THAN ORIGINAL DESIGN Original Independent 3rd Party LCA REPORT INTERNAL PROJECTIONS 79% below virgin PP 35% below virgin PP 58% below virgin PP Up to 87% below virgin PP Up to 2021 IRONTON ESTIMATES $9.7M/yr ENERGY OPEX (Electricity and Natural Gas Only) $3.8M Annual Savings Up to ELECTRICITY NATURAL GAS Consumption Actual VS Design 35-45% BELOW 50-60% BELOW Potential LCA Impact1 Potential Opex Reductions2 10-17% BELOW 15-20% BELOW $1.3-2.2M 1.2-2.0 CPP $1.2-1.6M 1.1-1.5 CPP Early Internal Estimates for Actual Energy Consumption 1. potential impact estimated against the values of the Boundless Impact LCA report for Ironton 2. assuming 107 million pounds of production, electricity rate 7 cents per kwh and natural gas is $7 per MCF

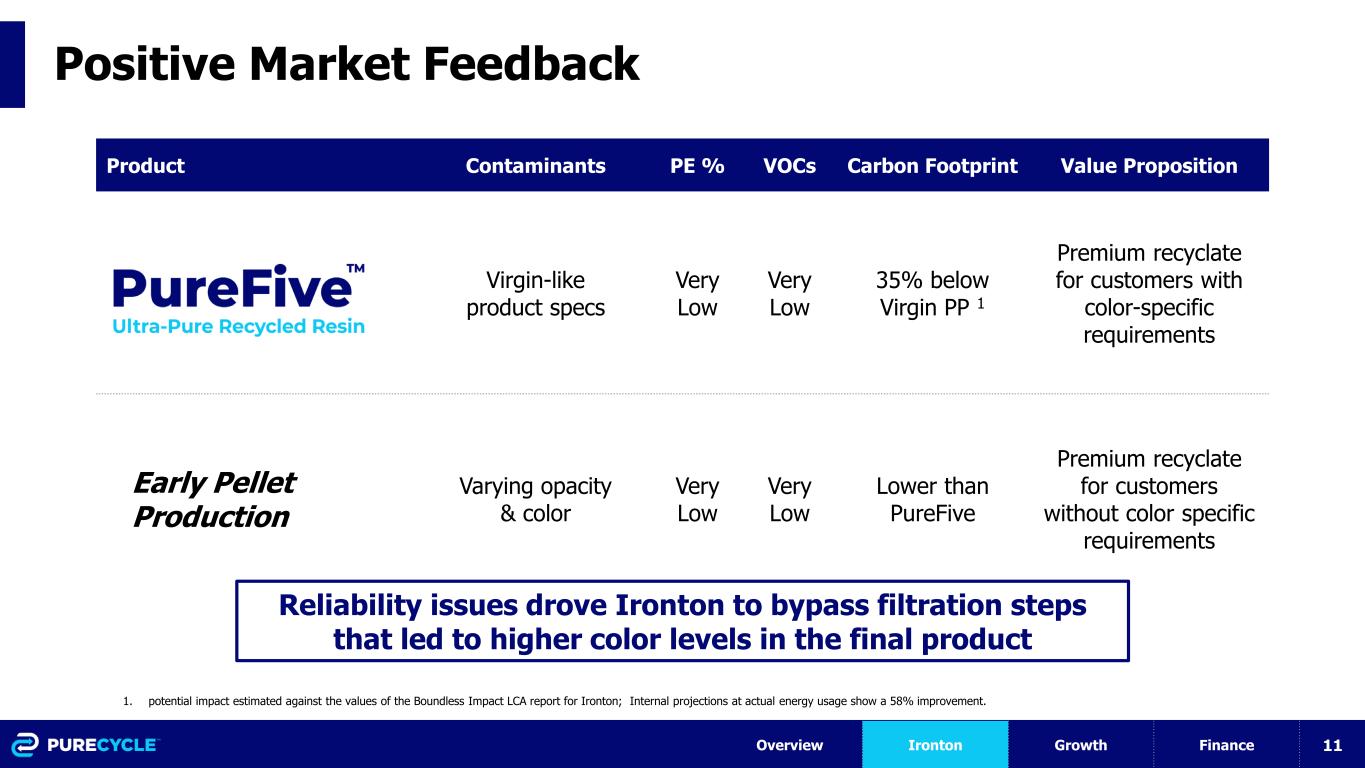

11Confidential Information. Do Not Distribute. Positive Market Feedback Product Contaminants PE % VOCs Carbon Footprint Value Proposition Virgin-like product specs Very Low Very Low 35% below Virgin PP 1 Premium recyclate for customers with color-specific requirements Early Pellet Production Varying opacity & color Very Low Very Low Lower than PureFive Premium recyclate for customers without color specific requirements Reliability issues drove Ironton to bypass filtration steps that led to higher color levels in the final product Overview Ironton Growth Finance 1. potential impact estimated against the values of the Boundless Impact LCA report for Ironton; Internal projections at actual energy usage show a 58% improvement.

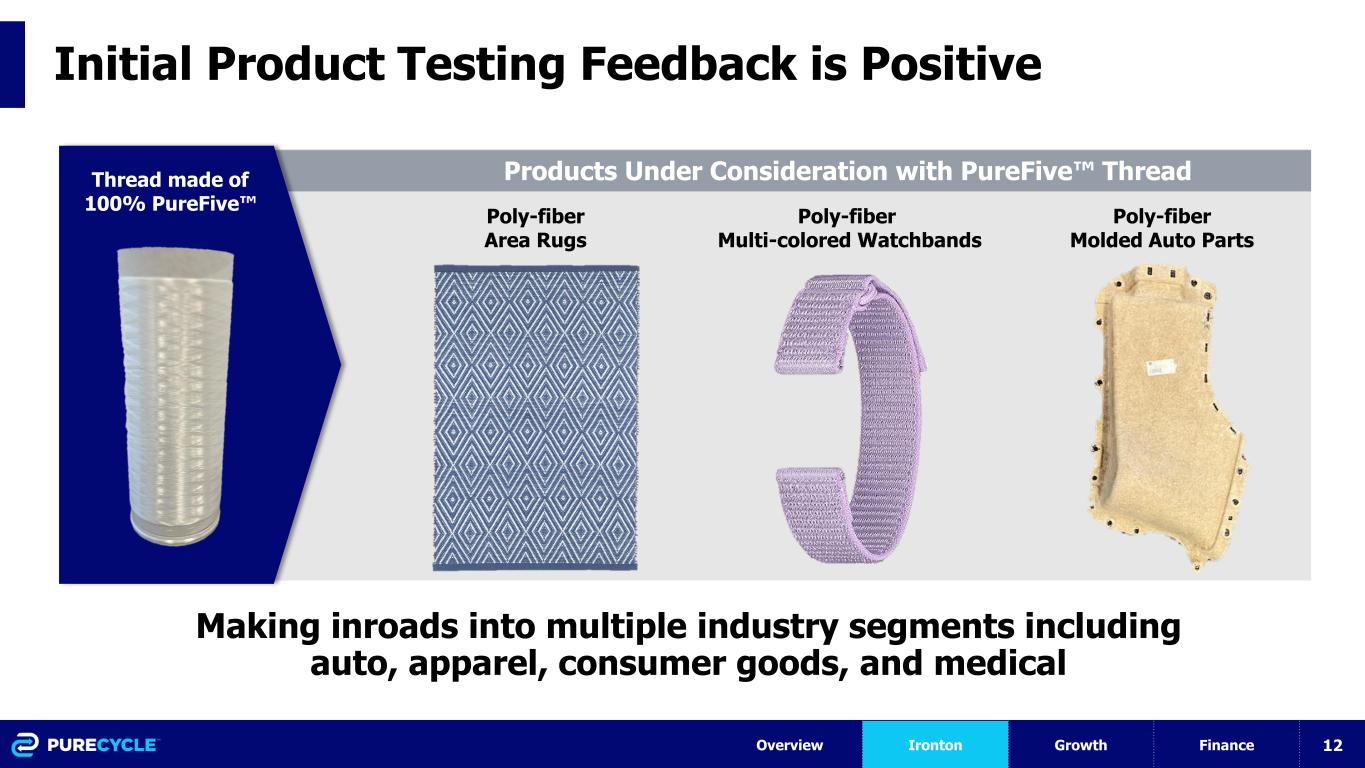

12Confidential Information. Do Not Distribute. Initial Product Testing Feedback is Positive Making inroads into multiple industry segments including auto, apparel, consumer goods, and medical Overview Ironton Growth Finance Poly-fiber Area Rugs Poly-fiber Multi-colored Watchbands Poly-fiber Molded Auto Parts Products Under Consideration with PureFive ThreadThread made of 100% PureFive

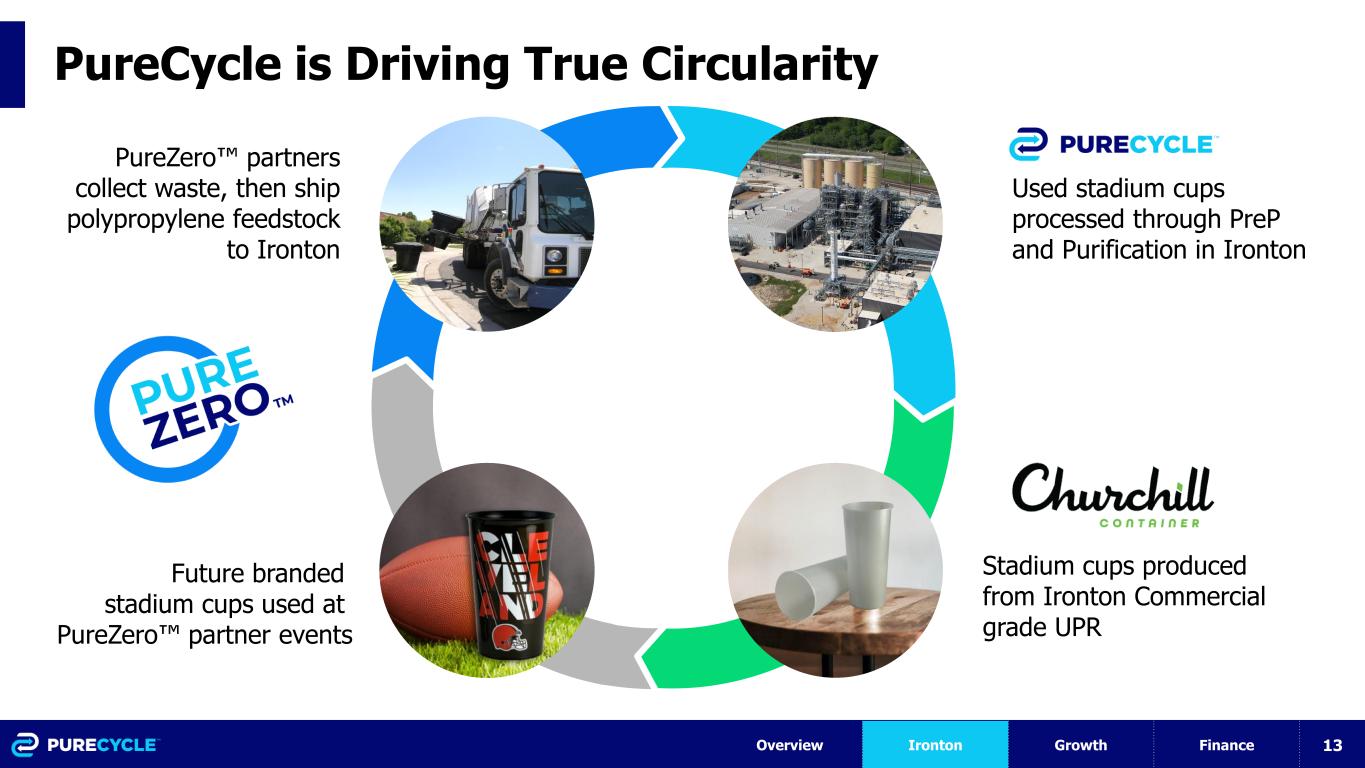

13Confidential Information. Do Not Distribute. PureCycle is Driving True Circularity Overview Ironton Growth Finance Used stadium cups processed through PreP and Purification in Ironton Stadium cups produced from Ironton Commercial grade UPR Future branded stadium cups used at PureZero partner events PureZero partners collect waste, then ship polypropylene feedstock to Ironton

14Confidential Information. Do Not Distribute. Achieve higher continuous plant rates Consistent product quality Qualify customers on commercial product Execute Q2 outage Near Term Focus to Advance Ironton Operations Overview Ironton Growth Finance

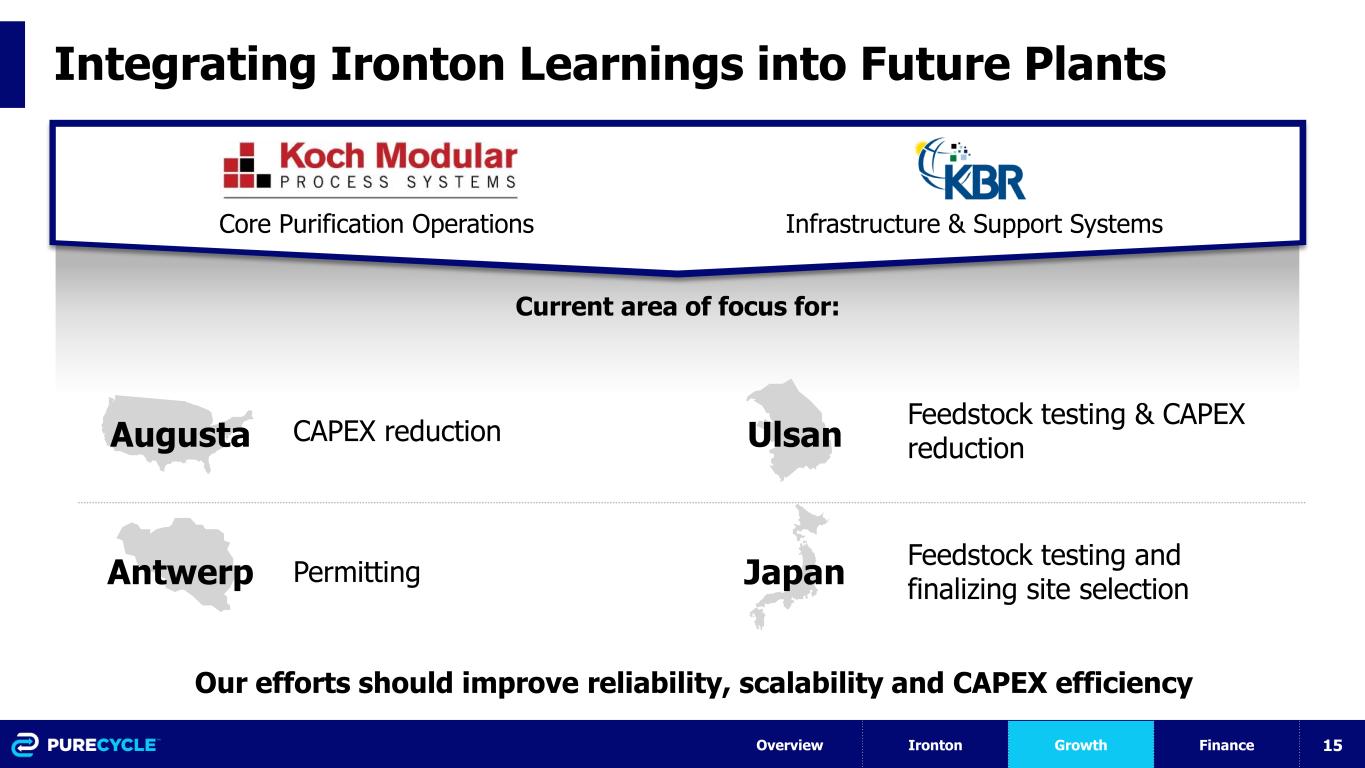

15Confidential Information. Do Not Distribute. Augusta CAPEX reduction Ulsan Feedstock testing & CAPEX reduction Antwerp Permitting Japan Feedstock testing and finalizing site selection Integrating Ironton Learnings into Future Plants Core Purification Operations Our efforts should improve reliability, scalability and CAPEX efficiency Current area of focus for: Overview Ironton Growth Finance Infrastructure & Support Systems

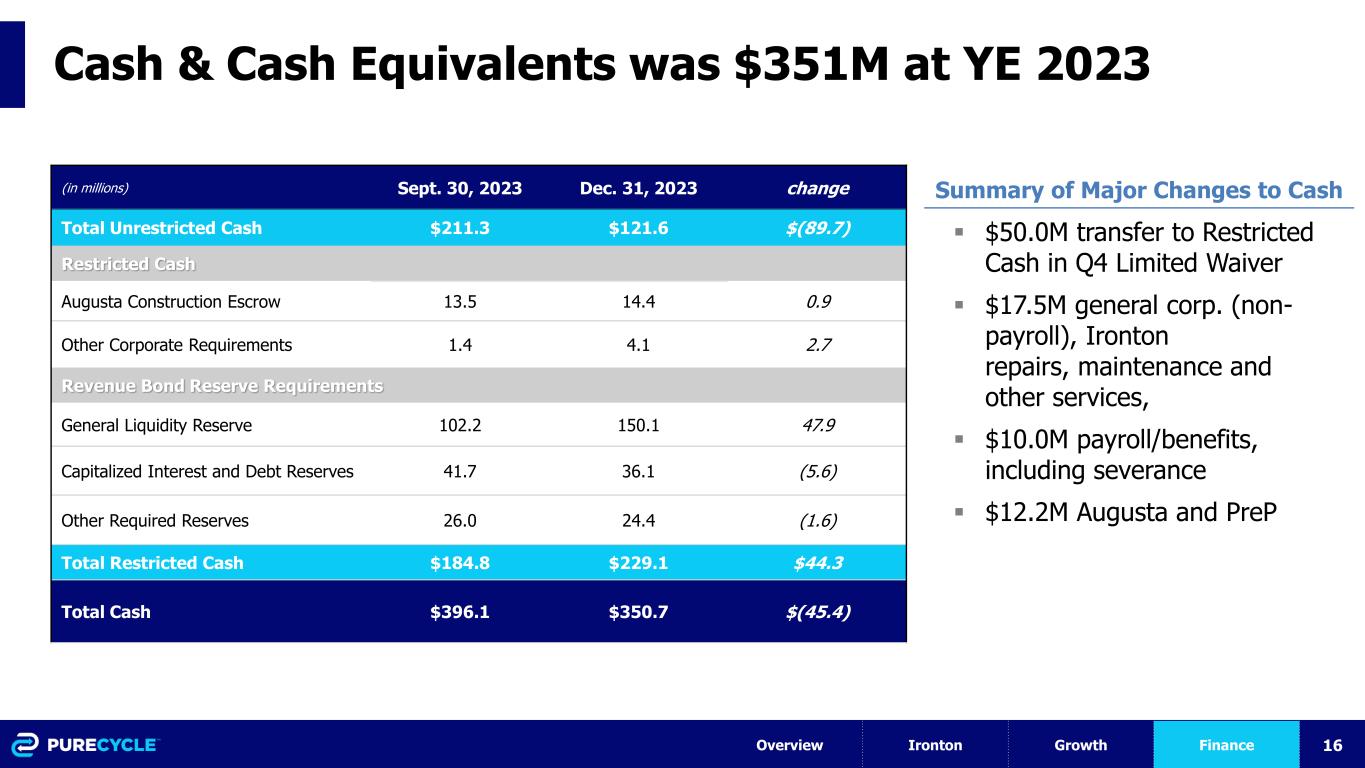

16Confidential Information. Do Not Distribute. Cash & Cash Equivalents was $351M at YE 2023 ▪ $50.0M transfer to Restricted Cash in Q4 Limited Waiver ▪ $17.5M general corp. (non- payroll), Ironton repairs, maintenance and other services, ▪ $10.0M payroll/benefits, including severance ▪ $12.2M Augusta and PreP Summary of Major Changes to Cash(in millions) Sept. 30, 2023 Dec. 31, 2023 change Total Unrestricted Cash $211.3 $121.6 $(89.7) Restricted Cash Augusta Construction Escrow 13.5 14.4 0.9 Other Corporate Requirements 1.4 4.1 2.7 Revenue Bond Reserve Requirements General Liquidity Reserve 102.2 150.1 47.9 Capitalized Interest and Debt Reserves 41.7 36.1 (5.6) Other Required Reserves 26.0 24.4 (1.6) Total Restricted Cash $184.8 $229.1 $44.3 Total Cash $396.1 $350.7 $(45.4) Overview Ironton Growth Finance

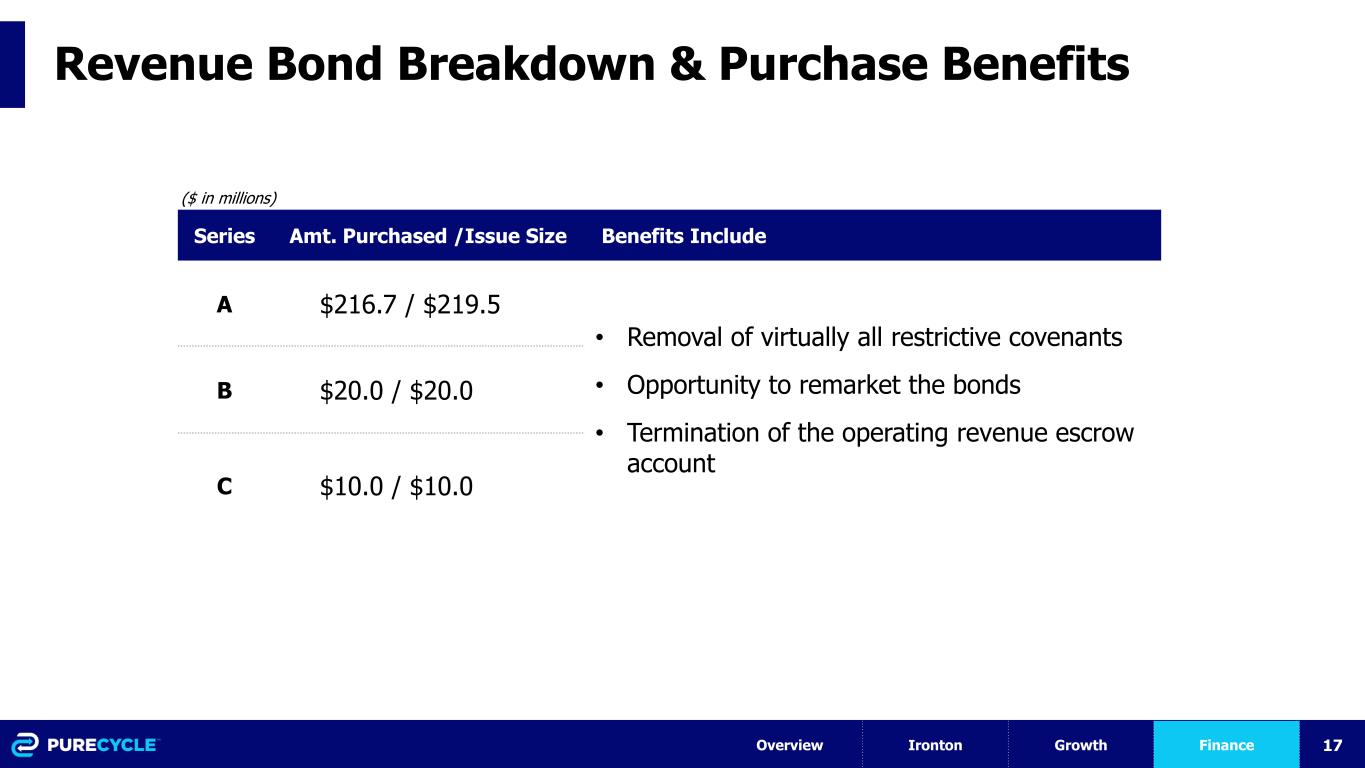

17Confidential Information. Do Not Distribute. Revenue Bond Breakdown & Purchase Benefits Series Amt. Purchased /Issue Size Benefits Include A $216.7 / $219.5 • Removal of virtually all restrictive covenants • Opportunity to remarket the bonds • Termination of the operating revenue escrow account B $20.0 / $20.0 C $10.0 / $10.0 Overview Ironton Growth Finance ($ in millions)

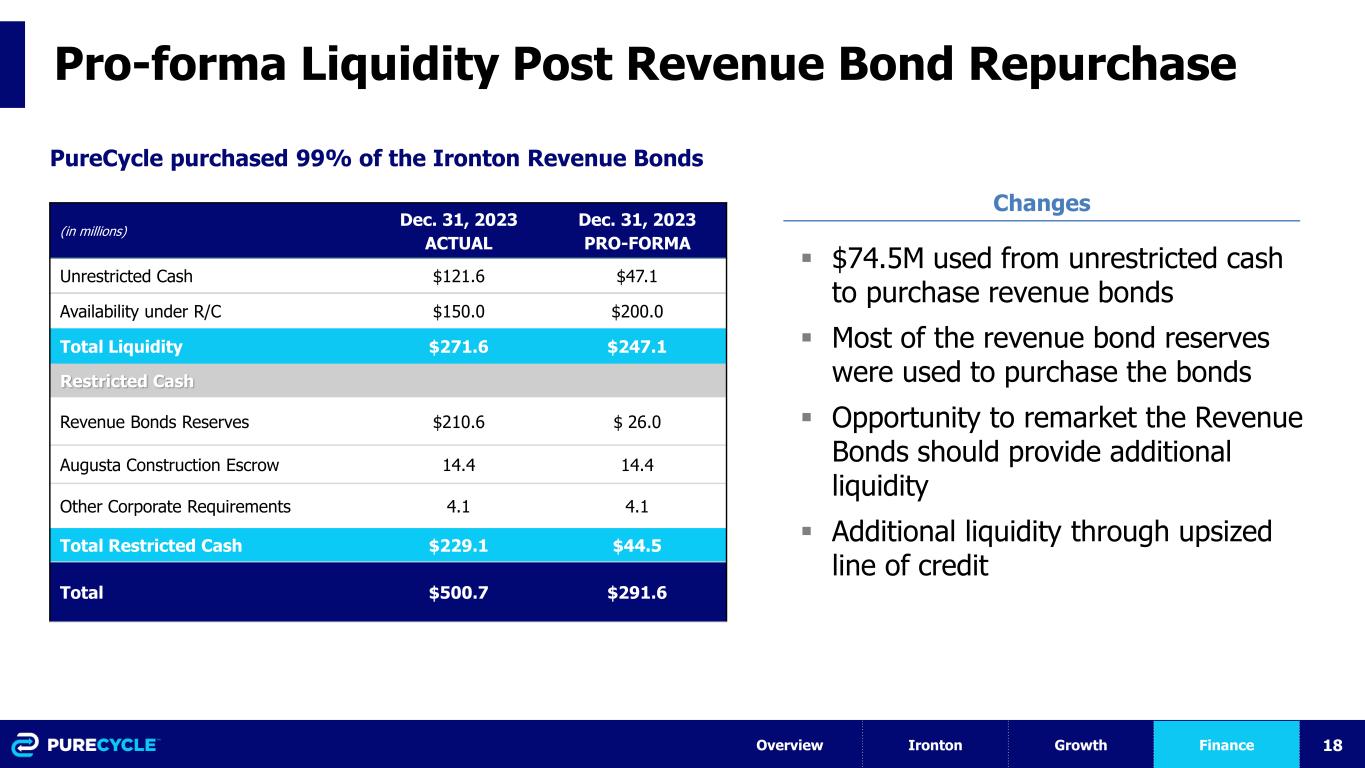

18Confidential Information. Do Not Distribute. Pro-forma Liquidity Post Revenue Bond Repurchase ▪ $74.5M used from unrestricted cash to purchase revenue bonds ▪ Most of the revenue bond reserves were used to purchase the bonds ▪ Opportunity to remarket the Revenue Bonds should provide additional liquidity ▪ Additional liquidity through upsized line of credit Changes (in millions) Dec. 31, 2023 ACTUAL Dec. 31, 2023 PRO-FORMA Unrestricted Cash $121.6 $47.1 Availability under R/C $150.0 $200.0 Total Liquidity $271.6 $247.1 Restricted Cash Revenue Bonds Reserves $210.6 $ 26.0 Augusta Construction Escrow 14.4 14.4 Other Corporate Requirements 4.1 4.1 Total Restricted Cash $229.1 $44.5 Total $500.7 $291.6 PureCycle purchased 99% of the Ironton Revenue Bonds Overview Ironton Growth Finance

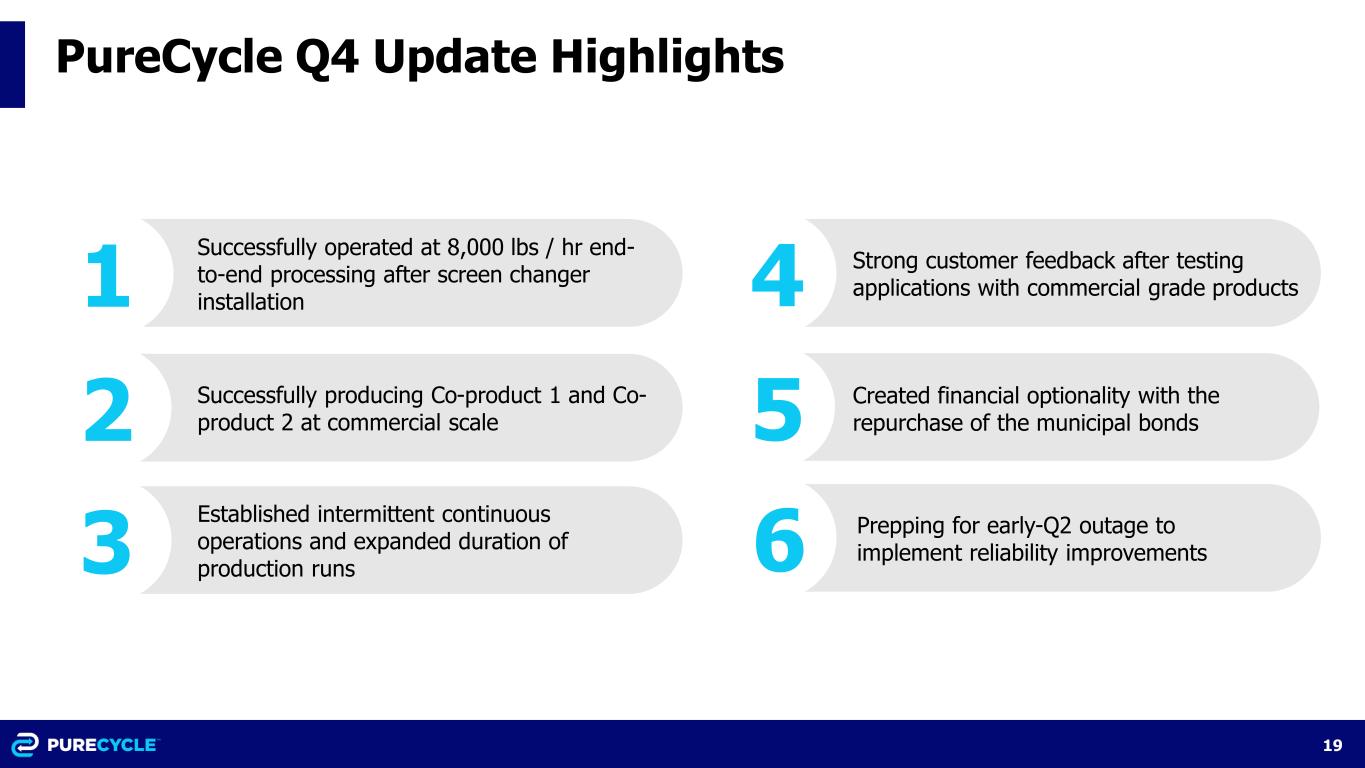

19Confidential Information. Do Not Distribute. PureCycle Q4 Update Highlights 1 2 3 4 5 Strong customer feedback after testing applications with commercial grade products Successfully operated at 8,000 lbs / hr end- to-end processing after screen changer installation Established intermittent continuous operations and expanded duration of production runs Created financial optionality with the repurchase of the municipal bonds Successfully producing Co-product 1 and Co- product 2 at commercial scale 6 Prepping for early-Q2 outage to implement reliability improvements