Exhibit 99.2

1 1 Third Quarter 2021 Corporate Update November 11, 2021

2 2 Forward - Looking Statements Certain statements in this Presentation contain forward - looking statements within the meaning of Section 27A of the Securities A ct of 1933, as amended (the “Securities Act”), and Section 21E of the Securities Exchange Act of 1934, as amended (the “Exchange Act”), including statements about the outco me of any legal or regulatory proceedings to which PureCycle Technologies, Inc. (“PCT”) is, or may become a party, and the financial condition, results of operations, ear nin gs outlook and prospects of PureCycle Technologies, Inc. (“PCT”). Forward - looking statements generally relate to future events or our future financial or operating pe rformance and may refer to projections and forecasts. Forward - looking statements are typically identified by words such as “plan,” “believe,” “expect,” “anticipate,” “inte nd,” “outlook,” “estimate,” “forecast,” “project,” “continue,” “could,” “may,” “might,” “possible,” “potential,” “predict,” “should,” “would” and other similar words and expres sio ns (or the negative versions of such words or expressions), but the absence of these words does not mean that a statement is not forward - looking. The forward - looking statements are based on the current expectations of the management of PCT and are inherently subject to unce rtainties and changes in circumstances and their potential effects and speak only as of this Presentation. There can be no assurance that future developments will b e t hose that have been anticipated. These forward - looking statements involve a number of risks, uncertainties or other assumptions that may cause actual results or performance to be materially different from those expressed or implied by these forward - looking statements. These risks and uncertainties include, but are not limited to, those factors des cribed in the section of the Company’s Quarterly Report on Form 10 - Q (the “Form 10 - Q”) entitled “Risk Factors,” those discussed and identified in public filings made with the SE C by PCT, and the following: PCT's ability to meet, and to continue to meet, applicable regulatory requirements for the use of PCT’s ultra - pure recycled polypropylene (“UPRP” ) in food grade applications (both in the United States and abroad); PCT's ability to comply on an ongoing basis with the numerous regulatory requirements applicable t o t he UPRP and PCT’s facilities (both in the United States and abroad); Expectations and changes regarding PCT’s strategies and future financial performance, including it s f uture business plans, expansion plans or objectives, prospective performance and opportunities and competitors, revenues, products and services, pricing, operating ex pen ses, market trends, liquidity, cash flows and uses of cash, capital expenditures, and PCT’s ability to invest in growth initiatives; PCT’s ability to scale and build the I ron ton plant in a timely and cost - effective manner; PCT’s ability to build its first cluster facility, located in Augusta, Georgia in a timely and cost - effective manner; PCT’s ability to sort and process polypropylene plastic waste at its plastic waste prep (“Feed PreP ”) facilities; PCT’s ability to maintain exclusivity under The Procter & Gamble Company license; the implementation, market a cce ptance and success of PCT’s business model and growth strategy; the success or profitability of PCT’s offtake arrangements; the ability to source feedstock with a high polypropylene content; PCT’s future capital requirements and sources and uses of cash; PCT’s ability to obtain funding for its operations a nd future growth; developments and projections relating to PCT’s competitors and industry; the outcome of any legal or regulatory proceedings to which PCT is, or may become a party, including recently filed securities class action case; the ability to recognize the anticipated benefits of the Business Combination (as defined in the Form 10 - Q); unexpe cted costs related to the Business Combination; geopolitical risk and changes in applicable laws or regulations; the possibility that PCT may be adversely affected by other eco nomic, business, and/or competitive factors; operational risk; and the risk that the COVID - 19 pandemic, including any variants and the efficacy and distribution of vaccines, and local, state, federal and international responses to addressing the pandemic may have an adverse effect on PCT’s business operations, as well as PCT’s financial cond iti on and results of operations. PCT specifically disclaims any obligation to update this Presentation. These forward - looking statements should not be relied upon as representing PCT’s assessments as of any date subsequent to the date of this Presentation. Accordingly, undue reliance should not be placed upon the forward - looking statements.

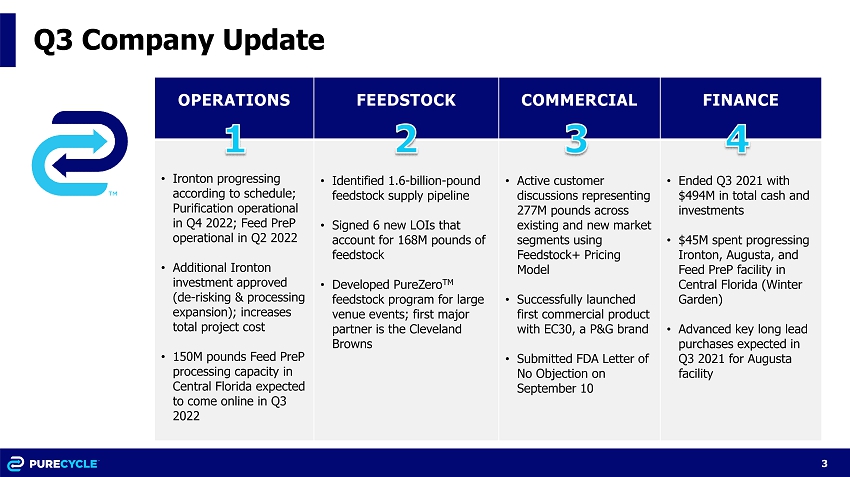

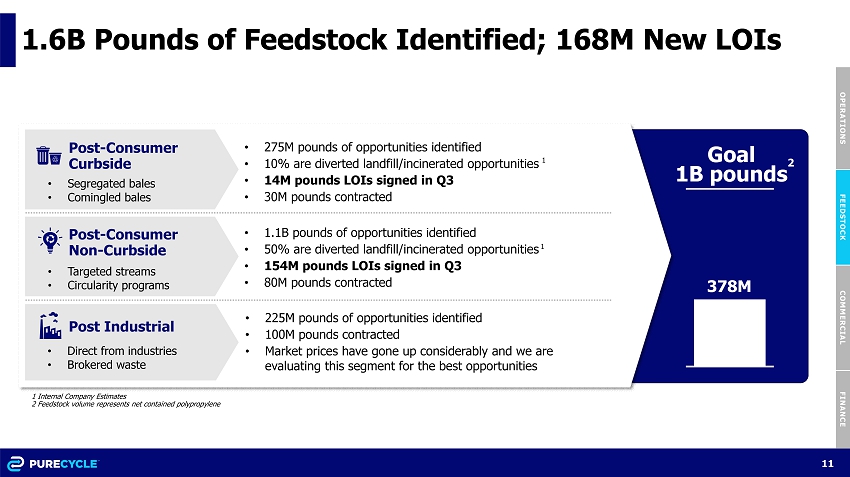

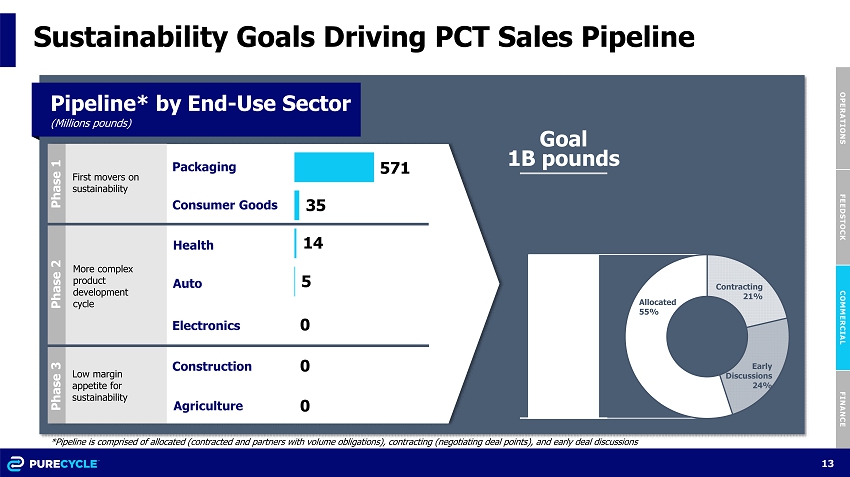

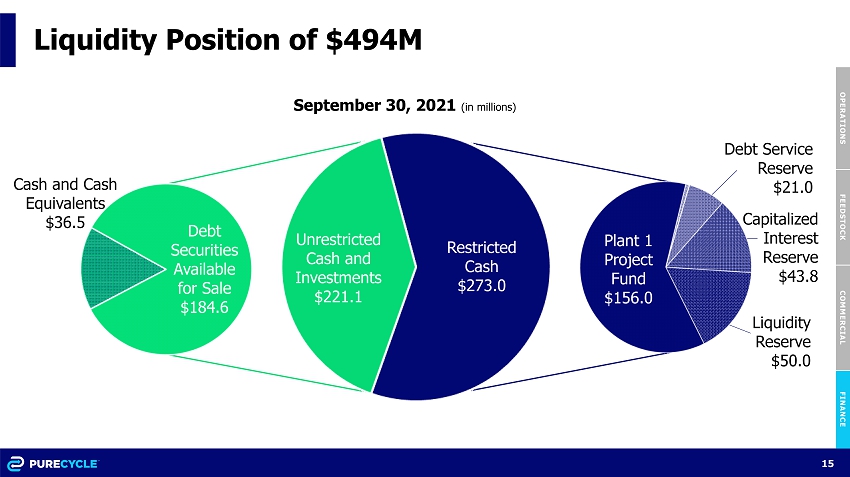

3 3 Q3 Company Update OPERATIONS FEEDSTOCK COMMERCIAL FINANCE • Ironton progressing according to schedule; Purification operational in Q4 2022; Feed PreP operational in Q2 2022 • Additional Ironton investment approved (de - risking & processing expansion); increases total project cost • 150M pounds Feed PreP processing capacity in Central Florida expected to come online in Q3 2022 • Identified 1.6 - billion - pound feedstock supply pipeline • Signed 6 new LOIs that account for 168M pounds of feedstock • Developed PureZero TM feedstock program for large venue events; first major partner is the Cleveland Browns • Active customer discussions representing 277M pounds across existing and new market segments using Feedstock+ Pricing Model • Successfully launched first commercial product with EC30, a P&G brand • Submitted FDA Letter of No Objection on September 10 • Ended Q3 2021 with $494M in total cash and investments • $45M spent progressing Ironton, Augusta, and Feed PreP facility in Central Florida (Winter Garden) • Advanced key long lead purchases expected in Q3 2021 for Augusta facility

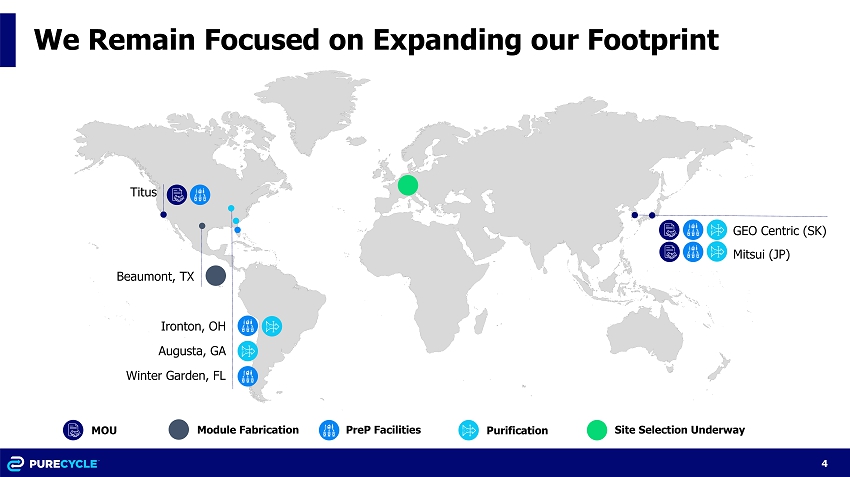

4 4 We Remain Focused on Expanding our Footprint Titus GEO Centric (SK) PreP Facilities Purification Site Selection Underway Winter Garden, FL Ironton, OH Augusta, GA MOU Mitsui (JP) Module Fabrication Beaumont, TX

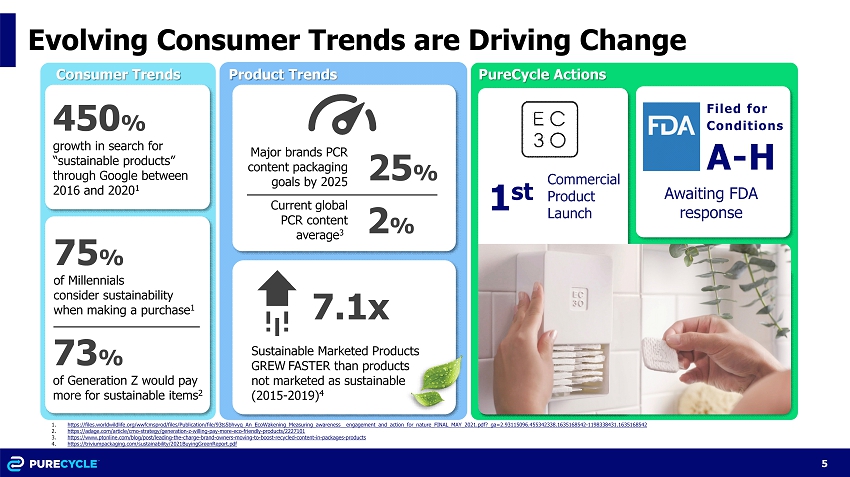

5 5 Evolving Consumer Trends are Driving Change 1. https://files.worldwildlife.org/wwfcmsprod/files/Publication/file/93ts5bhvyq_An_EcoWakening_Measuring_awareness__engagement_a nd_ action_for_nature_FINAL_MAY_2021.pdf?_ga=2.93115096.455342338.1635168542 - 1198338431.1635168542 2. https://adage.com/article/cmo - strategy/generation - z - willing - pay - more - eco - friendly - products/2227101 3. https://www.ptonline.com/blog/post/leading - the - charge - brand - owners - moving - to - boost - recycled - content - in - packages - products 4. https://triviumpackaging.com/sustainability/2021BuyingGreenReport.pdf Filed for Conditions A - H 450 % growth in search for “sustainable products” through Google between 2016 and 2020 1 75 % of Millennials consider sustainability when making a purchase 1 73 % of Generation Z would pay more for sustainable items 2 25 % Major brands PCR content packaging goals by 2025 7.1x Consumer Trends Product Trends Sustainable Marketed Products GREW FASTER than products not marketed as sustainable (2015 - 2019) 4 PureCycle Actions Current global PCR content average 3 2 % Awaiting FDA response Commercial Product Launch 1 st

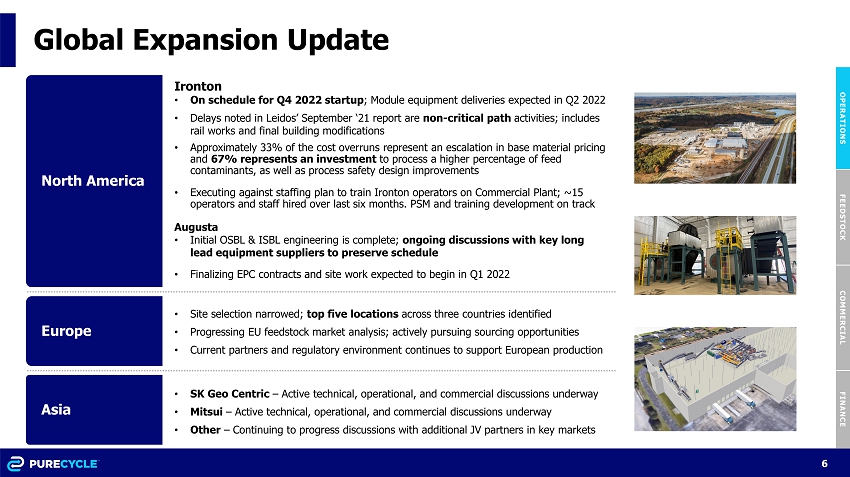

6 6 Global Expansion Update Ironton • On schedule for Q4 2022 startup ; Module equipment deliveries expected in Q2 2022 • Delays noted in Leidos’ September ‘21 report are non - critical path activities; includes rail works and final building modifications • Approximately 33% of the cost overruns represent an escalation in base material pricing and 67% represents an investment to process a higher percentage of feed contaminants, as well as process safety design improvements • Executing against staffing plan to train Ironton operators on Commercial Plant; ~15 operators and staff hired over last six months. PSM and training development on track Augusta • Initial OSBL & ISBL engineering is complete; ongoing discussions with key long lead equipment suppliers to preserve schedule • Finalizing EPC contracts and site work expected to begin in Q1 2022 North America Asia • SK Geo Centric – Active technical, operational, and commercial discussions underway • Mitsui – Active technical, operational, and commercial discussions underway • Other – Continuing to progress discussions with additional JV partners in key markets • Site selection narrowed; top five locations across three countries identified • Progressing EU feedstock market analysis; actively pursuing sourcing opportunities • Current partners and regulatory environment continues to support European production OPERATIONS FEEDSTOCK COMMERCIAL FINANCE Europe

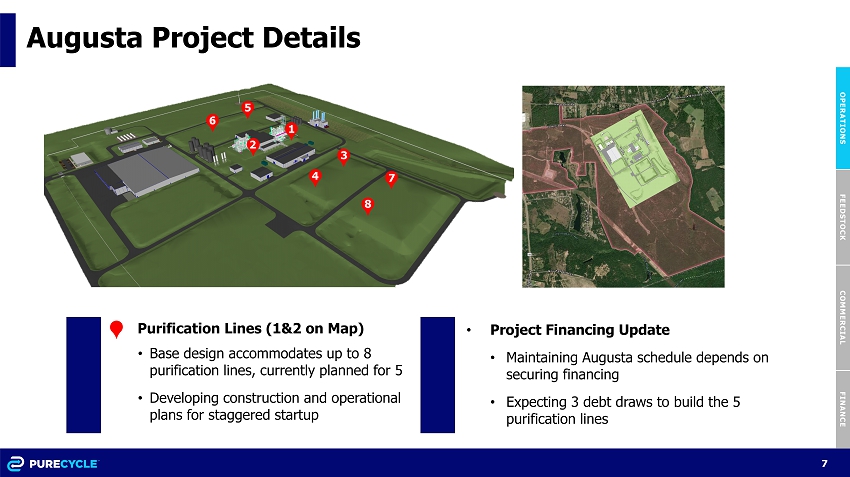

7 7 • Project Financing Update • Maintaining Augusta schedule depends on securing financing • Expecting 3 debt draws to build the 5 purification lines Augusta Project Details OPERATIONS FEEDSTOCK COMMERCIAL FINANCE 2 4 1 3 5 6 7 8 • Purification Lines (1&2 on Map) • Base design accommodates up to 8 purification lines, currently planned for 5 • Developing construction and operational plans for staggered startup

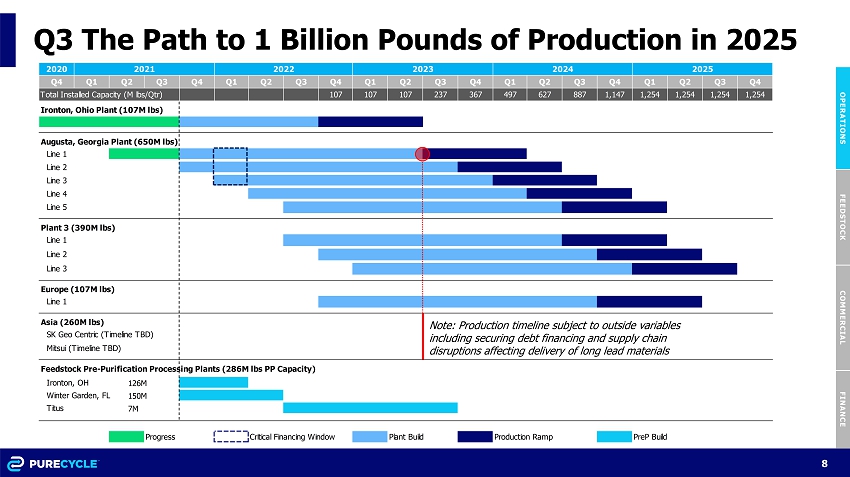

8 8 2020 Q4 Q1 Q3 Q2 Q3 Q1 Q2 Q4 Q3 Q4 Q1 Q2 Q3 Q4 107 107 367 887 1,147 1,254 1,254 1,254 1,254 Ironton, Ohio Plant (107M lbs) Annual Line Capacity: 107M lbs Augusta, Georgia Plant (650M lbs) Annual Line Capacity: 130MM lbs Line 1 Line 2 Line 3 Line 4 Line 5 Plant 3 (390M lbs) Line 1 Line 2 Line 8 Line 3 Europe (107M lbs) Line 1 Asia (260M lbs) SK Geo Centric (Timeline TBD) Mitsui (Timeline TBD) Feedstock Pre-Purification Processing Plants (286M lbs PP Capacity) Ironton, OH 126M Winter Garden, FL 150M Titus 7M Progress Critical Financing Window Plant Build Production Ramp PreP Build 2021 2022 2023 2024 2025 Q2 Total Installed Capacity (M lbs/Qtr) 107 237 497 627 Q2 Q1 Q4 Q3 Q1Q4 Q3 The Path to 1 Billion Pounds of Production in 2025 OPERATIONS FEEDSTOCK COMMERCIAL FINANCE Note: Production timeline subject to outside variables including securing debt financing and supply chain disruptions affecting delivery of long lead materials

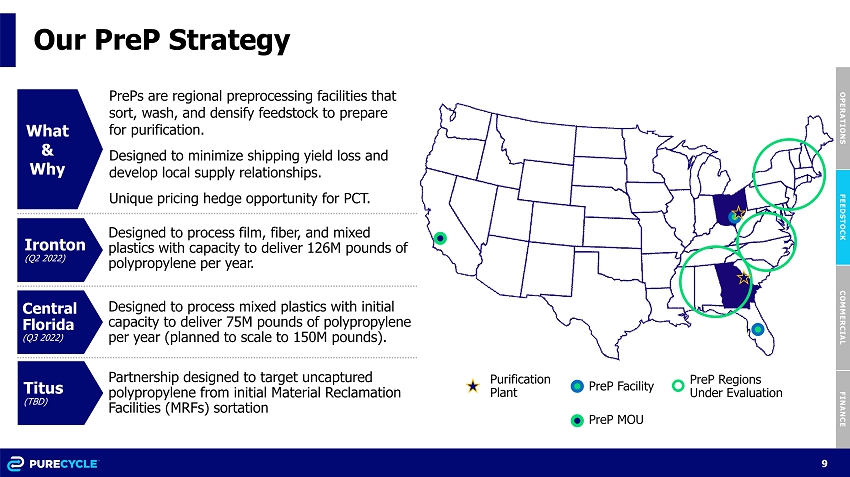

9 9 Our PreP Strategy PrePs are regional preprocessing facilities that sort, wash, and densify feedstock to prepare for purification. Designed to minimize shipping yield loss and develop local supply relationships. Unique pricing hedge opportunity for PCT. What & Why Designed to process film, fiber, and mixed plastics with capacity to deliver 126M pounds of polypropylene per year. PreP Facility Purification Plant OPERATIONS FEEDSTOCK COMMERCIAL FINANCE PreP Regions Under Evaluation Ironton (Q2 2022) Central Florida (Q3 2022) Titus (TBD) Partnership designed to target uncaptured polypropylene from initial Material Reclamation Facilities (MRFs) sortation Designed to process mixed plastics with initial capacity to deliver 75M pounds of polypropylene per year (planned to scale to 150M pounds). PreP MOU

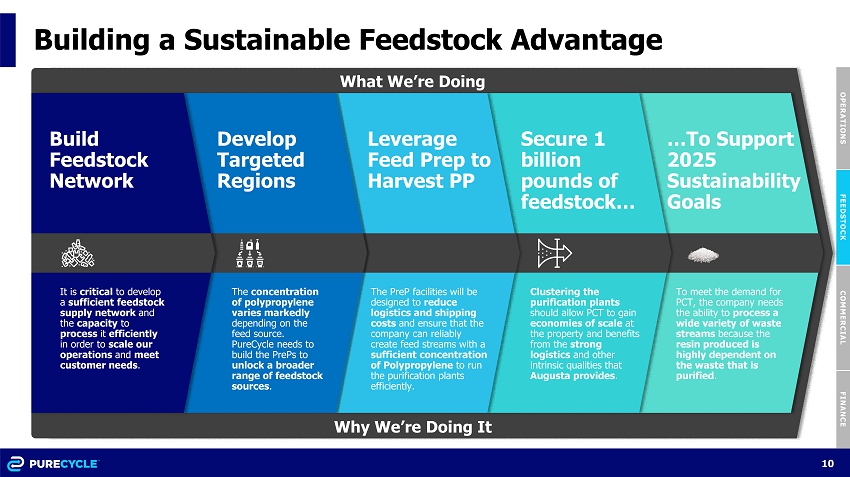

10 10 OPERATIONS FEEDSTOCK COMMERCIAL FINANCE Build Feedstock Network Develop Targeted Regions Leverage Feed Prep to Harvest PP Secure 1 billion pounds of feedstock… To meet the demand for PCT, the company needs the ability to process a wide variety of waste streams because the resin produced is highly dependent on the waste that is purified . Building a Sustainable Feedstock Advantage It is critical to develop a sufficient feedstock supply network and the capacity to process it efficiently in order to scale our operations and meet customer needs . The concentration of polypropylene varies markedly depending on the feed source. PureCycle needs to build the PrePs to unlock a broader range of feedstock sources . The PreP facilities will be designed to reduce logistics and shipping costs and ensure that the company can reliably create feed streams with a sufficient concentration of Polypropylene to run the purification plants efficiently. Clustering the purification plants should allow PCT to gain economies of scale at the property and benefits from the strong logistics and other intrinsic qualities that Augusta provides . …To Support 2025 Sustainability Goals What We’re Doing Why We’re Doing It

11 11 1.6B Pounds of Feedstock Identified; 168M New LOIs Post Industrial Post - Consumer Non - Curbside Post - Consumer Curbside • Segregated bales • Comingled bales • Targeted streams • Circularity programs • Direct from industries • Brokered waste OPERATIONS FEEDSTOCK COMMERCIAL FINANCE Goal 1B pounds 1 Internal Company Estimates 2 Feedstock volume represents net contained polypropylene • 275M pounds of opportunities identified • 10% are diverted landfill/incinerated opportunities • 14M pounds LOIs signed in Q3 • 30M pounds contracted • 1.1B pounds of opportunities identified • 50% are diverted landfill/incinerated opportunities • 154M pounds LOIs signed in Q3 • 80M pounds contracted • 225M pounds of opportunities identified • 100M pounds contracted • Market prices have gone up considerably and we are evaluating this segment for the best opportunities 2 1 1 378M

12 12 that Drive Circularity PureCycle Awareness PureZero TM Program

13 13 Sustainability Goals Driving PCT Sales Pipeline OPERATIONS FEEDSTOCK COMMERCIAL FINANCE Packaging Construction Consumer Goods Health Auto Pipeline* by End - Use Sector (Millions pounds) Agriculture Electronics First movers on sustainability Low margin appetite for sustainability Phase 1 Phase 2 Phase 3 More complex product development cycle Goal 1B pounds *Pipeline is comprised of allocated (contracted and partners with volume obligations), contracting (negotiating deal points), an d early deal discussions Contracting 21% Early Discussions 24% Allocated 55% 571 35 14 5 0 0 0

14 14 PureCycled Polypropylene…from Post - Consumer Feedstock Ultra - Pure Recycled Polypropylene Blow Molded Bottle 50% PCT Resin Storage Container 100% PCT Resin Hinge Closure 100% PCT Resin Simple Closure 100% PCT Resin EC30 Case 95 % PCT Resin 1st Commercial Product

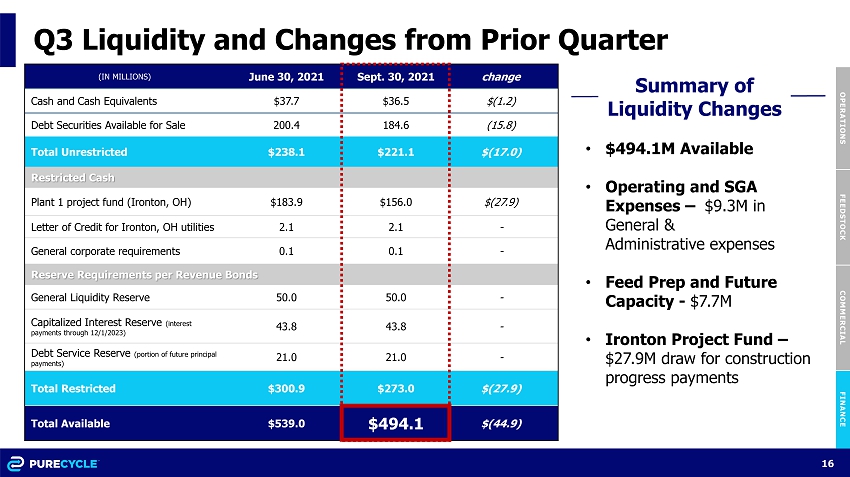

15 15 Liquidity Position of $494M Capitalized Interest Reserve $43.8 Debt Service Reserve $21.0 September 30, 2021 (in millions) Liquidity Reserve $50.0 Cash and Cash Equivalents $36.5 Unrestricted Cash and Investments $221.1 Debt Securities Available for Sale $184.6 Restricted Cash $273.0 Plant 1 Project Fund $156.0 OPERATIONS FEEDSTOCK COMMERCIAL FINANCE

16 16 Q3 Liquidity and Changes from Prior Quarter (IN MILLIONS) June 30, 2021 Sept. 3 0, 2021 change Cash and Cash Equivalents $37.7 $36.5 $(1.2) Debt Securities Available for Sale 200.4 184.6 (15.8) Total Unrestricted $238.1 $221.1 $(17.0) Restricted Cash Plant 1 project fund (Ironton, OH) $183.9 $156.0 $(27.9) Letter of Credit for Ironton, OH utilities 2.1 2.1 - General corporate requirements 0.1 0.1 - Reserve Requirements per Revenue Bonds General Liquidity Reserve 50.0 50.0 - Capitalized Interest Reserve (interest payments through 12/1/2023) 43.8 43.8 - Debt Service Reserve (portion of future principal payments) 21.0 21.0 - Total Restricted $300.9 $273.0 $(27.9) Total Available $539.0 $494.1 $(44.9) Summary of Liquidity Changes • $494.1M Available • Operating and SGA Expenses – $ 9.3 M in General & Administrative expenses • Feed Prep and Future Capacity - $7.7M • Ironton Project Fund – $27.9M draw for construction progress payments OPERATIONS FEEDSTOCK COMMERCIAL FINANCE

17 17 Key Takeaways for Today 1 2 3 6 7 Ironton remains on - track for Q4 2022 operation Developing 150M pounds of Feedstock PreP capacity in Orlando Strong pipeline with 277M pounds in active discussion 5 FDA Letter of No Objection “LNO" submission complete Invested in purification capability improvements in Ironton 1.6 billion pounds of feedstock identified; 168M in new LOIs signed 4 First PureCycled product launched with EC30, a P&G brand Launched new PureZero program to drive circularity 8

18 18 One Goal, A Pure Planet.