| PROSPECTUS SUPPLEMENT NO. 7 | Filed Pursuant to Rule 424(b)(3) |

| (to prospectus dated March 19, 2021) | Registration No. 333-251034 |

PURECYCLE TECHNOLOGIES, INC.

25,000,000 Shares

Common Stock

This prospectus supplement is being filed to update and supplement the information contained in the prospectus dated March 19, 2021 (as supplemented or amended from time to time, the “Prospectus”), with the information contained in our Current Report on Form 8-K, which was filed with the Securities and Exchange Commission (“SEC”) on June 23, 2021 (the “Form 8-K”). Accordingly, we have attached the Form 8-K to this prospectus supplement.

The Prospectus and this prospectus supplement relate to the resale from time to time of up to 25,000,000 shares of our common stock, par value $0.001 per share (“Common Stock”), issued pursuant to the terms of those certain subscription agreements entered into (the “PIPE Investment”) in connection with the Business Combination (as defined in the Prospectus). As described in the Prospectus, the selling securityholders named therein or their permitted transferees (collectively, the “Selling Stockholders”), may sell from time to time up to 25,000,000 shares of our Common Stock that were issued to the Selling Stockholders in connection with the closing of the PIPE Investment and the Business Combination.

This prospectus supplement updates and supplements the information in the Prospectus and is not complete without, and may not be delivered or utilized except in combination with, the Prospectus, including any amendments or supplements thereto. This prospectus supplement should be read in conjunction with the Prospectus and if there is any inconsistency between the information in the Prospectus and this prospectus supplement, you should rely on the information in this prospectus supplement.

Our Common Stock, warrants and units are listed on The Nasdaq Capital Market under the symbols “PCT,” “PCTTW” and “PCTTU,” respectively. On June 23, 2021, the closing price of our Common Stock was $25.14 per share.

Investing in our securities involves risks that are described in the “Risk Factors” section beginning on page 23 of the Prospectus.

Neither the Securities and Exchange Commission nor any state securities commission has approved or disapproved of these securities or determined if the Prospectus or this prospectus supplement is truthful or complete. Any representation to the contrary is a criminal offense.

The date of this prospectus supplement is June 23, 2021.

united states

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 8-K

CURRENT REPORT

Pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934

Date of Report (Date of earliest event reported): June 23, 2021

| PURECYCLE TECHNOLOGIES, INC. | ||

| (Exact name of registrant as specified in its charter) |

| Delaware | 001-40234 | 86-2293091 | ||

| (State or Other Jurisdiction of Incorporation) |

(Commission File Number) | (I.R.S. Employer Identification No.) |

5950 Hazeltine National Drive, Suite 650 Orlando, Florida |

32822 | |

| (Address of principal executive offices) | (Zip Code) |

(877) 648-3565

(Registrant’s

telephone number,

including area code)

N/A

(Former name or former address, if changed since last report.)

Check the appropriate box below if the Form 8-K filing is intended to simultaneously satisfy the filing obligations of the registrant under any of the following provisions:

| ¨ | Written communications pursuant to Rule 425 under the Securities Act (17 CFR 230.425) |

| ¨ | Soliciting material pursuant to Rule 14a-12 under the Exchange Act (17 CFR 240.14a-12) |

| ¨ | Pre-commencement communications pursuant to Rule 14d-2(b) under the Exchange Act (17 CFR 240.14d-2(b)) |

| ¨ | Pre-commencement communications pursuant to Rule 13e-4(c) under the Exchange Act (17 CFR 240-13e-4(c)) |

Securities registered pursuant to Section 12(b) of the Act:

| Title of each class | Trading symbol(s) |

Name of each exchange on which registered | ||

| Common Stock, par value $0.001 per share | PCT | The Nasdaq Capital Market LLC | ||

| Warrants, each exercisable for one share of common stock, $0.001 par value per share, at an exercise price of $11.50 per share | PCTTW | The Nasdaq Capital Market LLC | ||

| Units, each consisting of one share of common stock, $0.001 par value per share, and three quarters of one warrant | PCTTU | The Nasdaq Capital Market LLC |

Indicate by check mark whether the registrant is an emerging growth company as defined in Rule 405 of the Securities Act of 1933 (§230.405 of this chapter) or Rule 12b-2 of the Securities Exchange Act of 1934 (§240.12b-2 of this chapter).

Emerging growth company x

If an emerging growth company, indicate by check mark if the registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards provided pursuant to Section 13(a) of the Exchange Act. ¨

Item 7.01 Regulation FD Disclosure

PureCycle Technologies, Inc. (the “Company”) will be hosting an Investor Day event at its Ironton, Ohio facility in Ironton, Ohio beginning at 9:30 Eastern Time on June 23, 2021. Company representatives will make presentations and provide a tour of the site. The Company is furnishing as Exhibits 99.1 through 99.4 to this Current Report on Form 8-K the presentation materials to be provided to, and discussed with, attendees at the Investor Day event. The presentations will also be available on the Company’s website on the Investor Relations page of the Company's website: www.purecycletech.com.

The information in this Current Report on Form 8-K (including the presentation materials attached as Exhibit 99.1 through 99.4 hereto), is being furnished pursuant to Item 7.01 of Form 8-K and shall not be deemed to be “filed” for the purposes of Section 18 of the Securities Exchange Act of 1934, as amended (the “Exchange Act”), or otherwise subject to the liabilities of that section, nor shall it be deemed to be incorporated by reference in any filing under the Securities Act of 1933, as amended, or the Exchange Act. This Current Report on Form 8-K will not be deemed an admission as to the materiality of any information contained herein (including the presentation materials attached as Exhibit 99.1 through 99.4 hereto).

Item 9.01 Financial Statements and Exhibits.

| (d) | Exhibits |

| Exhibit No. | Description | |

| 99.1 | Executive Summary, dated June 23, 2021. | |

| 99.2 | Feedstock Evaluation Unit Presentation, dated June 23, 2021. | |

| 99.3 | Feedstock Strategy and Research and Development Presentation, dated June 23, 2021. | |

| 99.4 | Operations Update Presentation, dated June 23, 2021. | |

| 104.1 | Cover Page Interactive Data File (formatted in Inline XBRL) |

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned hereunto duly authorized.

| Dated: June 23, 2021 | PURECYCLE TECHNOLOGIES, INC. | |

| By: | /s/ Michael Dee | |

| Name: | Michael Dee | |

| Title: | Chief Financial Officer | |

3

Exhibit 99.1

Investor Day: Executive Summary June 23, 2021

2 Investor Day | June 23, 2021 2 Investor Day: Executive Summary Opening remarks will be provided by Mike Otworth (Chief Executive Officer and Chairman of PureCycle Technologies, Inc.), Mike Train (Chief Sustainability Officer, Emerson Electric Co.), and Marcus Behrendt (Partner and CEO, BMW iVentures).

3 Investor Day | June 23, 2021 3 Investor Day: Executive Summary (Cont.) Following the opening remarks, investor day participants will receive presentations from management on the following topics: ▪ Overview of the Feedstock Evaluation Unit – PureCycle management will walk investors through the PureCycle purification process and discuss how the purification process is designed to remove waste plastic and other contaminants from polypropylene to transform waste polypropylene into virgin - like polypropylene. For more details see Exhibit Titled: “Investor Day_ FEU Overview”. ▪ Feedstock Strategy, R&D, and Procurement Approach – the Company will provide an overview of how both plastics and recycling has evolved from the 1930s and discuss PureCycle’s strategy for securing both mixed plastics and waste polypropylene. Chief Manufacturing Officer (Dustin Olson) will discuss the Research and Development prototype that pairs existing recycling equipment with mechanical innovations. For more details see Exhibit Titled: “Investor Day_ Feedstock Overview”. ▪ PureCycle Operations and Execution – PureCycle’s operational leadership team will discuss our strategy across: (i.) module construction and scaling, (ii.) delivering operational excellence and exceptional safety in plant operations, (iii.) discussing how a robust digital strategy shortens plant ramp up and reduces unplanned downtime, and (iv.) an update on how we’ve been collaborating with our partners to meet a broad range of polypropylene specifications. For more details see Exhibit Titled: “Investor Day_ Operations Update”.

Exhibit 99.2

Investor Day: FEU Overview June 23, 2021

STOP 1 SAFETY OVERVIEW Personal Protective Equipment Requirements PureCycle is currently still in a start-up phase. During this phase, the following PPE is required: Safety Glasses Hard Hats FR clothing FEU Hazards Currently, we are a Class 1, Division 2 area which does not allow for any electronics or sparking devices. (Storage lockers in hall.) In addition, please be mindful of slips, trips & falls as we are starting up the FEU. PHOTOGRAPHY IS PROHIBITED INSIDE THE PROCESS AREA

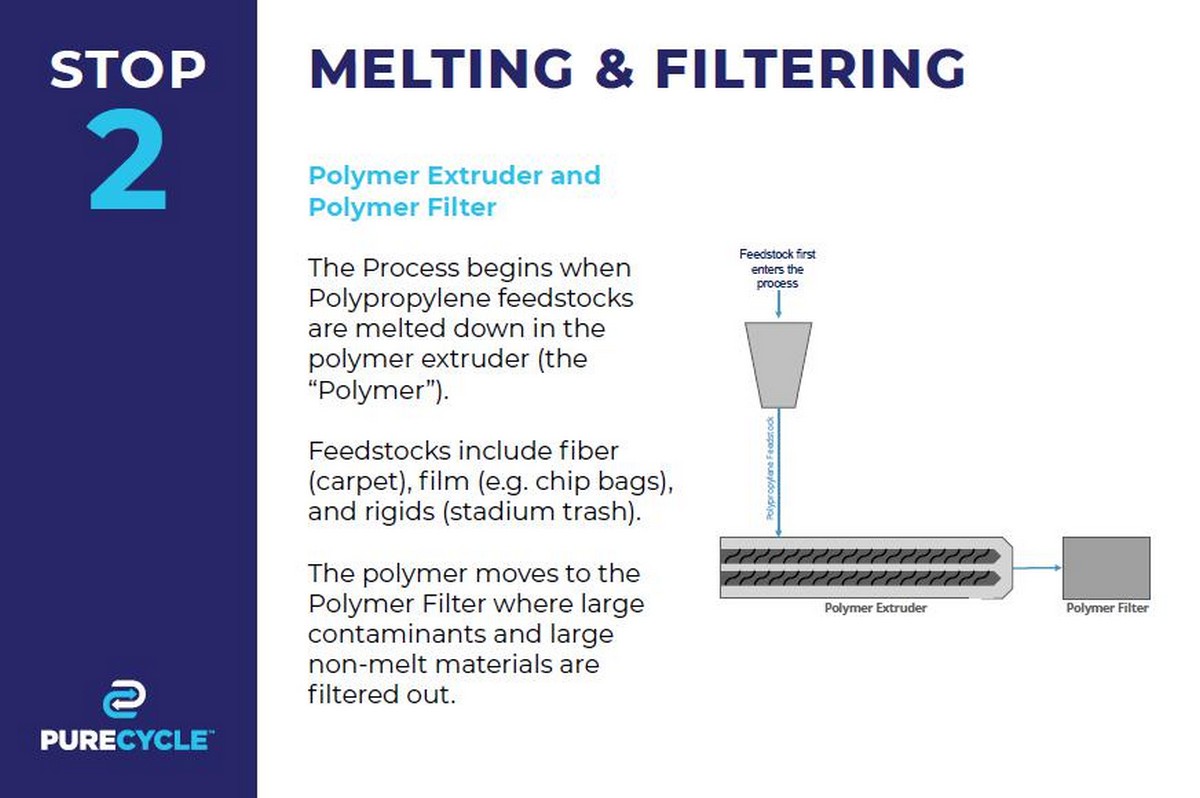

STOP 2 MELTING & FILTERING Polymer Extruder and Polymer Filter The Process begins when Polypropylene feedstocks are melted down in the polymer extruder (the “Polymer”). Feedstocks include fiber (carpet), film (e.g. chip bags), and rigids (stadium trash). The polymer moves to the Polymer Filter where large contaminants and large non-melt materials are filtered out. Polypropylene Feedstock Feedstock first enters the process Polymer Extruder Polymer Filter

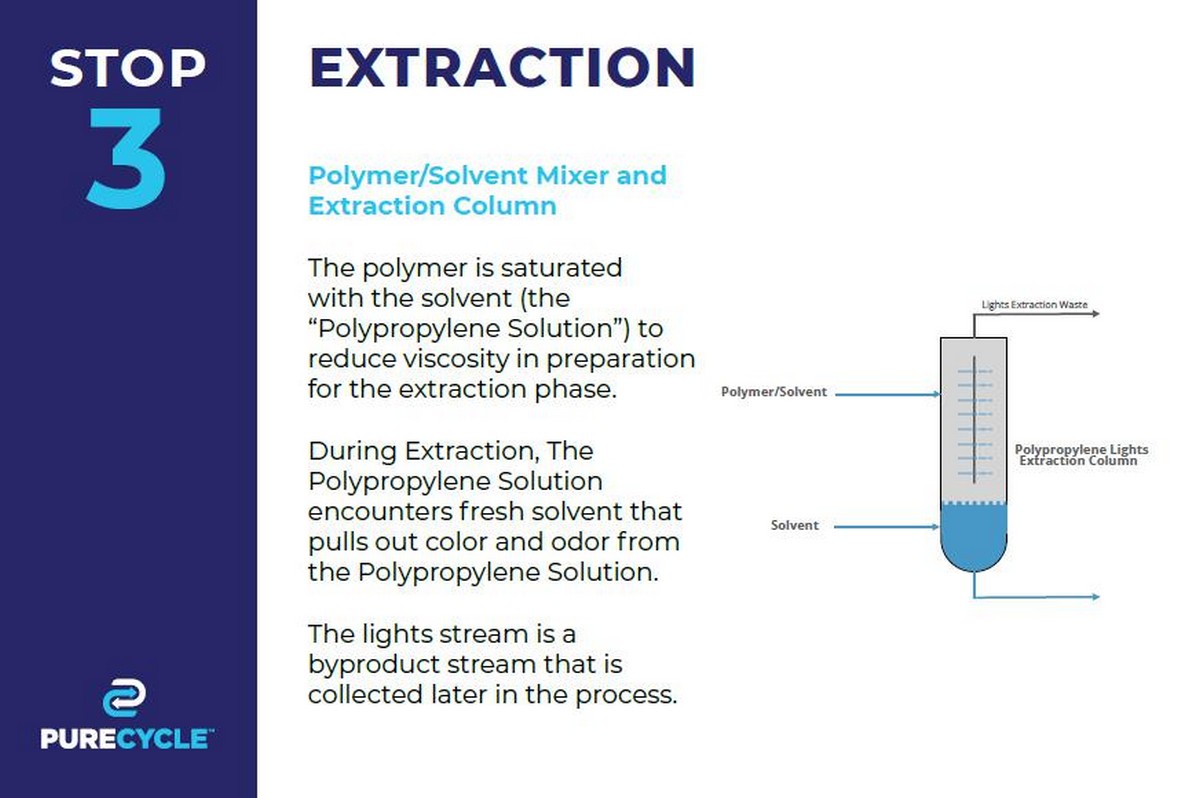

STOP 3 EXTRACTION Polymer/Solvent Mixer and Extraction Column The polymer is saturated with the solvent (the “Polypropylene Solution”) to reduce viscosity in preparation for the extraction phase. During Extraction, The Polypropylene Solution encounters fresh solvent that pulls out color and odor from the Polypropylene Solution. The lights stream is a byproduct stream that is collected later in the process. Lights Extraction Waste Polymer/Solvent Polypropylene Lights Extraction Column Solvent

STOP 4 MIXING & SETTLING Polymer Mixer and Large Particle Settler Additional Solvent is mixed with the Polypropylene Solution to reduce the polymer concentration. The Polyethylene/Solids settler allows insoluble solids and polymers to settle out of the process. These large particulates form a byproduct stream that is collected later in the process. Polyethylene/ Solids Settler Solids, Byproduct/Waste Polymer/Solvent Mixer

STOP 5 FILTERING Candle Filters The Polypropylene Solution is then filtered for smaller particulates, carried over from the decanter. Micron-sized particulates are captured by the vessels via the diatomaceous filter media. Candle Filter 1 Candle Filter 2

STOP 6 PURIFICATION Columns The Polypropylene Solution is further polished through contact with a solid, media packed, column. This step purifies the product through removal of pigments and other contaminants based on their physical and chemical properties. Column 1 Column 2 Column 3 Column 4

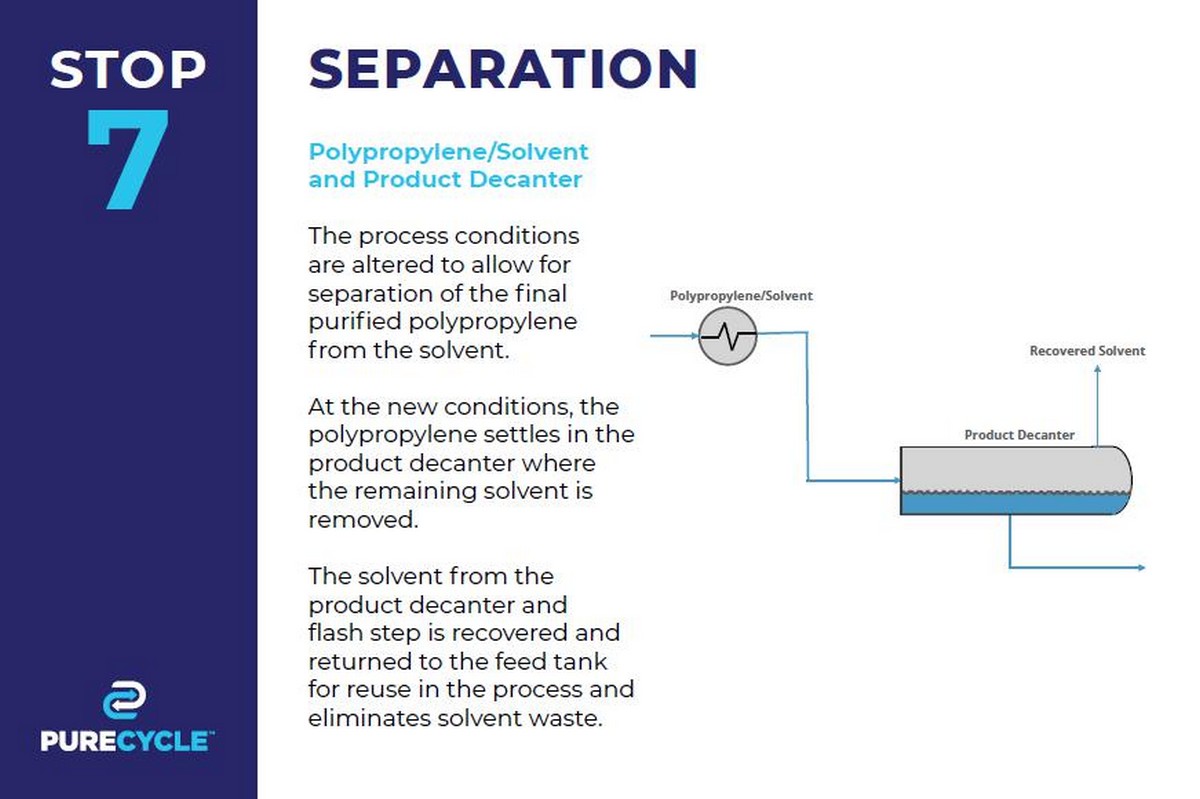

STOP 7 SEPARATION Polypropylene/Solvent and Product Decanter Polypropylene/Solvent and Product Decanter The process conditions are altered to allow for separation of the final purified polypropylene from the solvent. At the new conditions, the polypropylene settles in the product decanter where the remaining solvent is removed. The solvent from the product decanter and flash step is recovered and returned to the feed tank for reuse in the process and eliminates solvent waste. Polypropylene/Solvent Product Decanter Recovered Solvent

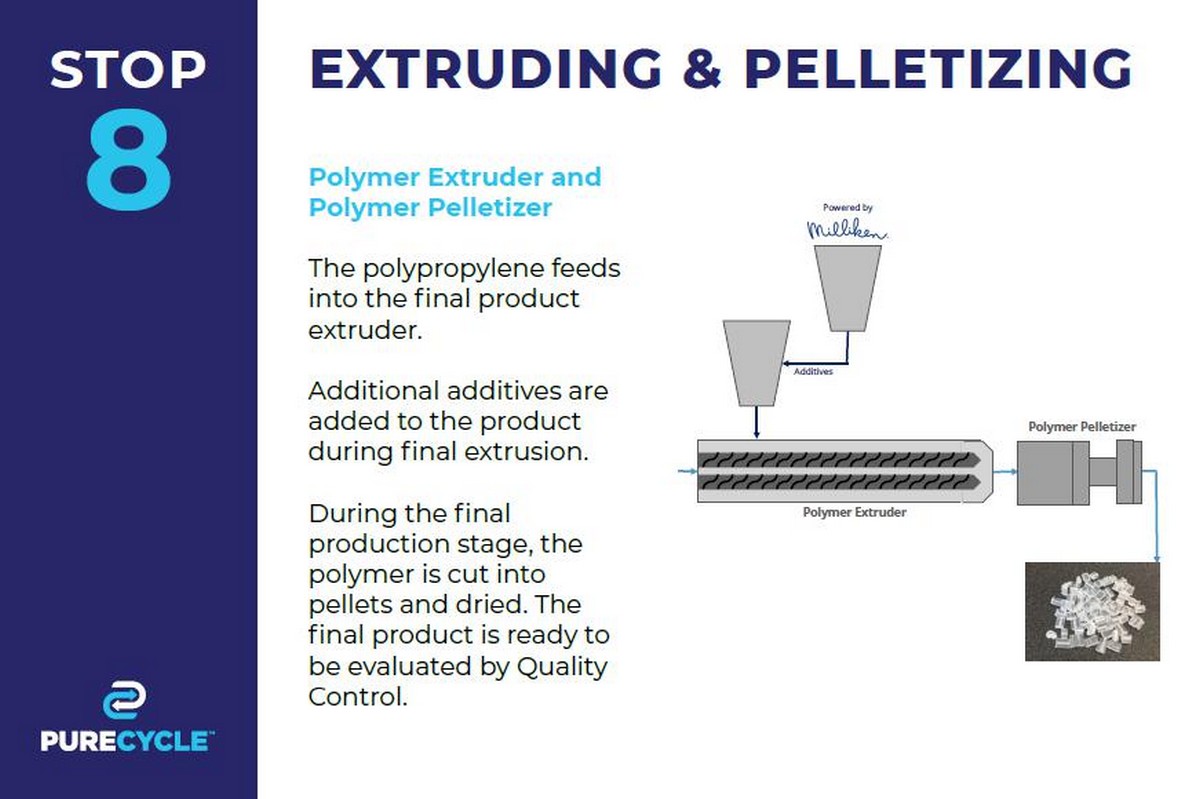

STOP 8 EXTRUDING & PELLETIZING Polymer Extruder and Polymer Pelletizer The polypropylene feeds into the final product extruder. Additional additives are added to the product during final extrusion. During the final production stage, the polymer is cut into pellets and dried. The final product is ready to be evaluated by Quality Control. Powered by Additives Polymer Pelletizer Polymer Extruder

STOP 9 FACILITY OVERVIEW 3D Model

Exhibit 99.3

Investor Day: Feedstock Overview June 23, 2021

2 Investor Day | June 23, 2021 2 Investor Day: Feedstock Overview PureCycle management discuss how both plastics and recycling has evolved from the 1930s to today and PureCycle’s strategy for securing both mixed plastics and waste polypropylene. Additionally, the Company discusses, that in line with its’ feedstock strategy, the Company is establishing a Feedstock R&D facility that is designed to process a range of (i.) bulky rigids, (ii.) tubs, lids, containers bales (iii.) #5 polypropylene bales, (iv.) mixed polypropylene bales, and (v.) #3 - #7 bales (“mixed plastics”) bales to evaluate the optimal pre - processing equipment and technologies to deliver the highest percentage of polypropylene feedstock into the purification process. The Feedstock R&D facility will couple processing equipment from Herbold with infrared sorting technology from TOMRA Systems and advanced polyolefin water separation technology from Impact Recycling.

1930s INNOVATION DURING WAR TIME Plastics original value proposition was to be a lighter, safer, better alternative to products used everyday. While Nylon was repurposed for military applications 1 , HDPE used in light weighting and held as a state secret. 2 The original invention of plastic made society more sustainable in the short term. Years until first mill accept plastics: 40 3 http://www.combat.ws/S4/MILTERMS/MT - G.HTM A https://www.seattlepi.com/business/slideshow/Boeing - military - aircraft - 142933.php B https://www.airforcemag.com/article/rise - of - the - air - corps/ C 1. https://www.sciencehistory.org/the - history - and - future - of - plastics 2. https://www.plasticsindustry.org/history - plastics 3. https://www.aaapolymer.com/history - of - plastic - recycling/ A B C ϭϵϲϬ ϭϵϳϬ ϭϵϴϬ ϭϵϵϬ ϮϬϬϬ ϮϬϬϱ ϮϬϭϬ ϮϬϭϱ ϮϬϮϬ ϮϬϮϱ ϮϬϯϬ

1950s THE EXPONENTIAL GROWTH OF PLASTICS Polyester first reached the market and is hailed as a wonder fiber. You could wash a garment, hang it up, and have it ready to wear in a couple of hours with no need for ironing! Plastic packaging replaces traditional packaging due to economical, convenient, and environmentally friendly attributes. Single use and disposal was not the primary value proposition of plastics initially. Plastics Production: 1.5M 1 Years until first mill accepts plastics: 20 2 ϭϵϲϬ ϭϵϳϬ ϭϵϴϬ ϭϵϵϬ ϮϬϬϬ ϮϬϬϱ ϮϬϭϬ ϮϬϭϱ ϮϬϮϬ ϮϬϮϱ ϮϬϯϬ https://www.pinterest.com/pin/319614904777749134/?d=t&mt=login A 264705156479 B https://hemaplastindustries.com/wp - content/uploads/2021/04/brochure.2.pdf C 1. https://journals.openedition.org/factsreports/5071 2. https://www.aaapolymer.com/history - of - plastic - recycling/ A B C TONS

1980s THE FOCUS ON RECYCLING BEGINS As we begin running out of landfill space the nation shifts their focus to recycling. Along with this renewed focus comes the Creation of Resin Identification Codes. However, as plastics became more ubiquitous and the cost of production continued to go down, there was not enough thought given to end of life waste processing or creating secondary applications for discarded plastics. Plastics Production: 6.8M 1 Tons Recycled: 20,000 1 | Recycling Rate: 0.30% ϭϵϲϬ ϭϵϳϬ ϭϵϴϬ ϭϵϵϬ ϮϬϬϬ ϮϬϬϱ ϮϬϭϬ ϮϬϭϱ ϮϬϮϬ ϮϬϮϱ ϮϬϯϬ https://www.yournec.org/have - you - been - recycling - wrong/ A https://pleasedrinksustainably.com/blog/the - boat - that - got - america - recycling B https://www.recyclelogos.org/recycling - symbols.htm C 1. https://www.epa.gov/facts - and - figures - about - materials - waste - and - recycling/plastics - material - specific - data A B C TONS

1990s NEW LEGISLATION AND PLASTIC STREAMS In the 90s we see collective interest in solving the existing problem, but as soon as we start solving the bottle problem, broader uses of a range of plastics emerge. This results in progress and investments on a select set of plastics, but doesn’t anticipate where the market is going. Thus, the recycling rate moves in a linear fashion after an exponential jump. Plastics Production: 17.1M 1 Tons Recycled: 2.5M 1 | Recycling Rate: 7.9% ϭϵϲϬ ϭϵϳϬ ϭϵϴϬ ϭϵϵϬ ϮϬϬϬ ϮϬϬϱ ϮϬϭϬ ϮϬϭϱ ϮϬϮϬ ϮϬϮϱ ϮϬϯϬ https://www.history.com/news/recycling - history - america A https://www.kdrv.com/content/news/Southern - Oregon - waste - management - companies - now - accepting - more - plastic - bottles - 569860351.html B https://roguedisposal.com/about - us/news/service - updates/get - ready - to - welcome - a - familiar - face - back - to - the - curbside - recycling - fami ly C 1. https://www.epa.gov/facts - and - figures - about - materials - waste - and - recycling/plastics - material - specific - data TONS A B C

EARLY 2000s RECYCLING CHALLENGES ARISE By the time we get to the era surrounding 2018 there’s a confluence of events. China stops taking mixed plastics, resins are mixed together, single stream recycling is in full swing to help make life for the consumer easier and only limited markets exist for grey and black resin. Flexible packaging gets mixed up with paper and newer applications demand recycling solutions, but there are limited dollars available to solve for this problem. Plastics Production: 35.6M 1 Tons Recycled: 3.1M 1 | Recycling Rate: 8.7% ϭϵϲϬ ϭϵϳϬ ϭϵϴϬ ϭϵϵϬ ϮϬϬϬ ϮϬϬϱ ϮϬϭϬ ϮϬϭϱ ϮϬϮϬ ϮϬϮϱ ϮϬϯϬ 1. https://www.epa.gov/facts - and - figures - about - materials - waste - and - recycling/plastics - material - specific - data TONS http://pops.moenv.gov.jo/EN/Pages/Project__Components A https://www.plasticstoday.com/recycling/report - investigates - failure - recycling - address - us - plastic - waste - problem B A B

THE FUTURE OF PLASTIC RENEWABLE RESOURCE WITH INFINITE USE PP is versatile and enabling the next renaissance of plastics recycling where innovations across all plastics are driving us towards a circular economy. It will take all of us to bring recycling rates to where they need to be. We believe that if a rPP resin can be offered that is interchangeable with virgin we’ll see even more PP applications emerge. Plastics Production: Linear Tons Recycled: Exponential ϭϵϲϬ ϭϵϳϬ ϭϵϴϬ ϭϵϵϬ ϮϬϬϬ ϮϬϬϱ ϮϬϭϬ ϮϬϭϱ ϮϬϮϬ ϮϬϮϱ ϮϬϯϬ https://www.worldfootwear.com/news/adidas - 1 - million - pairs - of - sneakers - made - from - ocean - trash/3055.html A https://www.elcarrocolombiano.com/autos - del - mundo/bmw - i4 - concept - un - coupe - de - cuatro - puertas - con - tesla - en - la - mira/ B https://www.cladglobal.com/architecture_design_news?codeid=337267 C 1. Extrapolated based on ~3.5% growth rate; GrandView Research ( https://www.grandviewresearch.com/industry - analysis/global - plastics - market ) B C A

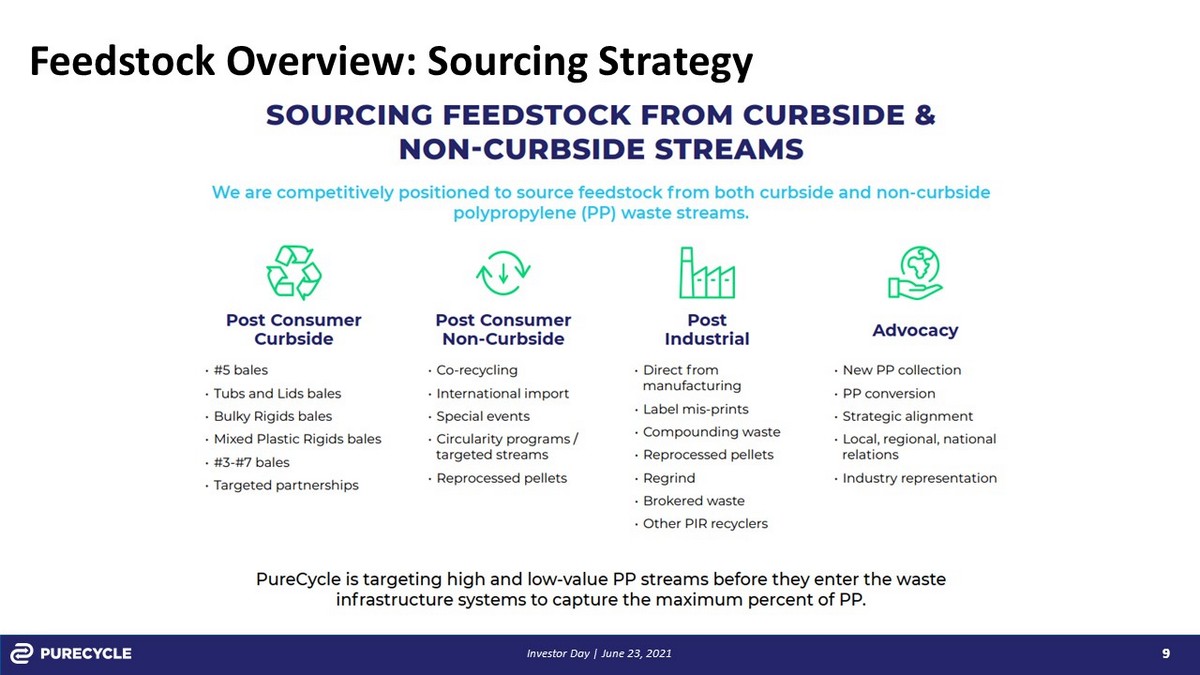

9 Investor Day | June 23, 2021 9 Feedstock Overview: Sourcing Strategy

10 Investor Day | June 23, 2021 10 Feedstock Overview: R&D Facility

Exhibit 99.4

Investor Day: Operations Update June 23, 2021

2 Investor Day | June 23, 2021 2 Investor Day: Operations Update PureCycle management discusses the following elements of execution: ▪ Construction Update for Plant 1 ▪ Operating Principles that are driving the company towards achieving operational excellence ▪ Digital Strategy and the benefits of being “born digital” ▪ Commercial Collaboration with Milliken & Company to deliver a virgin - like resin with no tradeoffs

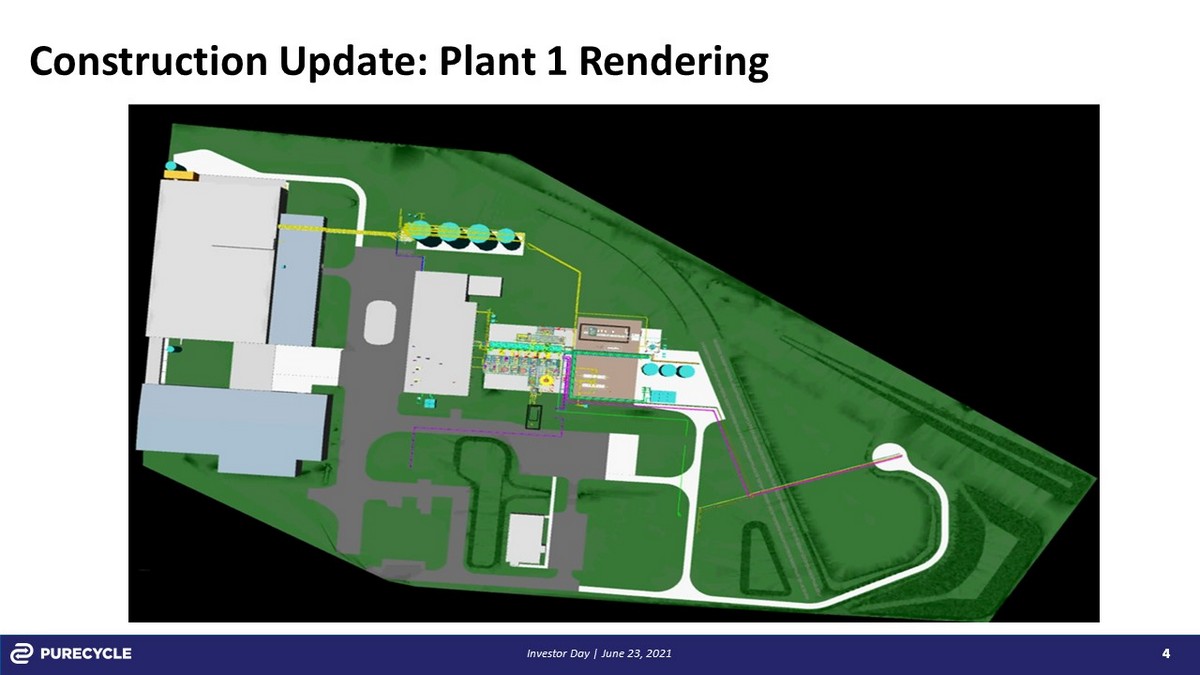

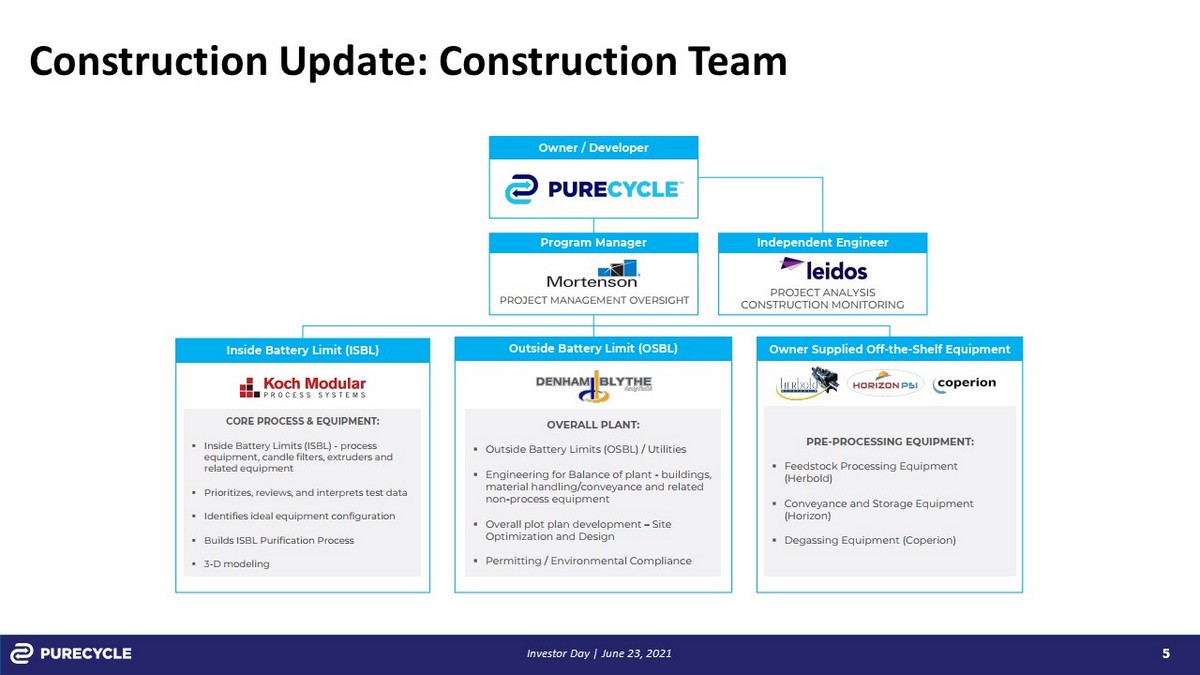

3 Investor Day | June 23, 2021 3 Construction Update PureCycle management discussed progress of construction activities. Koch Modular Process Systems (KMPS) has sub - contracted module fabrication work to GulfSpan Industrial LLC; Denham - Blythe Company, Inc. (DB) also plans to sub - contract on - site module integration work to GulfSpan Industrial LLC. This further integrates Plant 1 activities across KMPS and DB and aligns with the Plant 1 Construction Team efforts. The Operational Management team will also walk participants through the computer generated rendering of the site Additionally, the Company reports that according to the May 2021 Independent Engineer Report, which was released on June 18, 2021, the construction of the Ohio Facility remains on track. The full report for the month of May can be found here: https://emma.msrb.org/MarketActivity/ContinuingDisclosureDetails/P21122610

4 Investor Day | June 23, 2021 4 Construction Update: Plant 1 Rendering

5 Investor Day | June 23, 2021 5 Construction Update: Construction Team

6 Investor Day | June 23, 2021 6 Construction Update: Gulfspan Facility

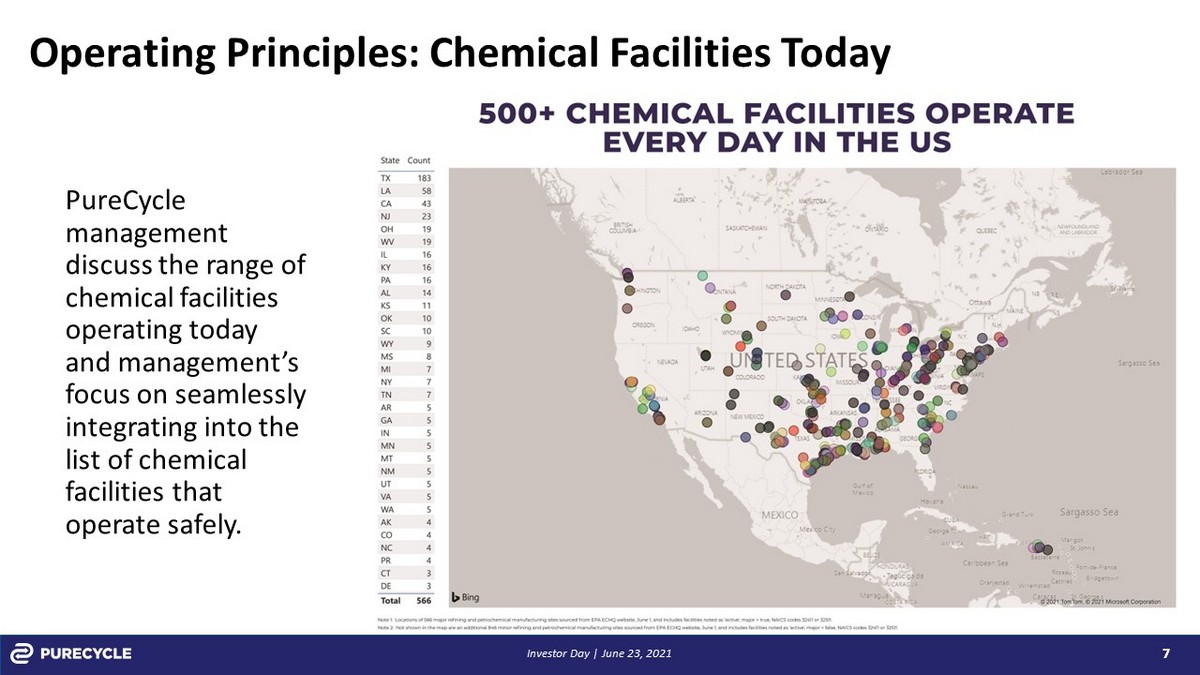

7 Investor Day | June 23, 2021 7 Operating Principles: Chemical Facilities Today PureCycle management discuss the range of chemical facilities operating today and management’s focus on seamlessly integrating into the list of chemical facilities that operate safely.

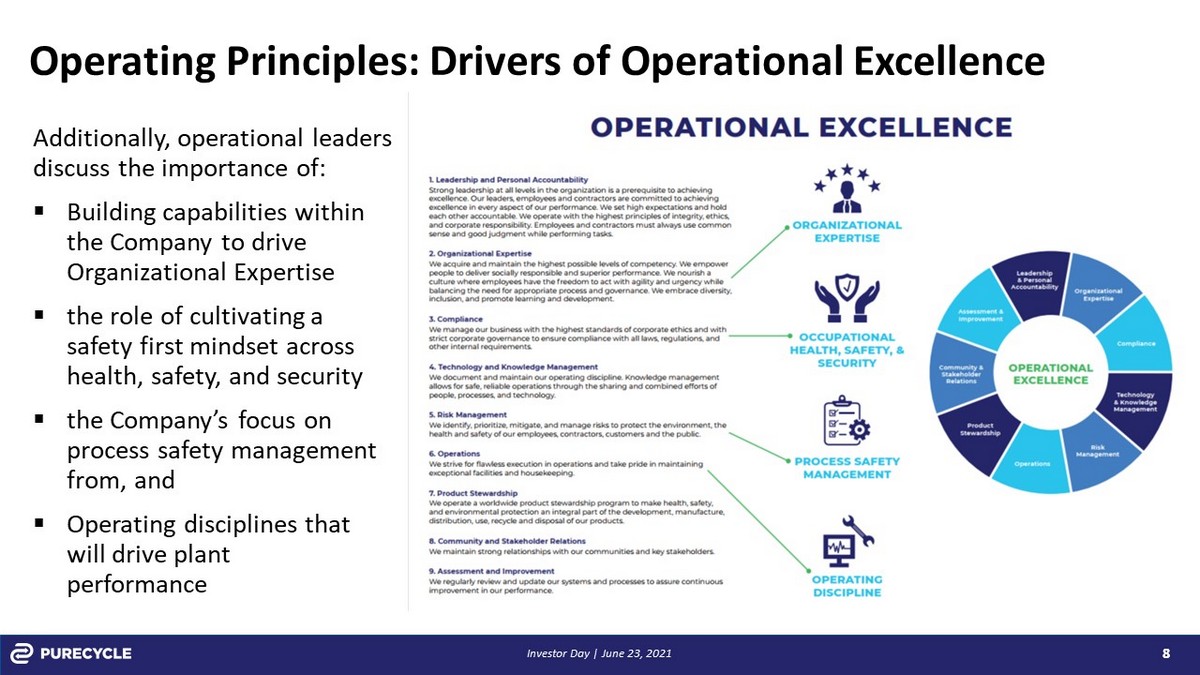

8 Investor Day | June 23, 2021 8 Operating Principles: Drivers of Operational Excellence Additionally, operational leaders discuss the importance of: ▪ Building capabilities within the Company to drive Organizational Expertise ▪ the role of cultivating a safety first mindset across health, safety, and security ▪ the Company’s focus on process safety management from, and ▪ Operating disciplines that will drive plant performance

9 Investor Day | June 23, 2021 9 Digital Strategy PureCycle management discusses how its’ collaboration with Emerson Electric and other digital companies is designed to reduce operating costs, improve efficiency, and enhance safety. The digital development includes the creation of a physical digital twin model that can be used across: ▪ Operations ▪ Reliability ▪ Maintenance ▪ Engineering and ▪ Health and safety Presenting data in in a lifelike 3D visualization helps users fully understand the context of that data. In addition to the fully implemented physical Digital twin, PureCycle will be implementing Emerson Automation Solutions Optic Analytics, as well as AMS - Asset Monitoring and health analysis algorithms that provide predictive intelligence and integrated protection technologies to reach business goals and achieve top - quartile reliability.

10 Investor Day | June 23, 2021 10 Commercial Collaboration with Milliken & Company PureCycle management in collaboration with leaders from Milliken & Company discuss how their commercial and R&D collaboration has changed since they formed their partnership in March 2019. The Company will discuss how customers are looking to both blend UPRP with virgin resin as well as deliver 100% UPRP into their products. Members of PureCycle management will showcase Ultra - Pure Recycled Polypropylene (UPRP) that was produced from the Feedstock Evaluation Unit (FEU) and the feedstocks that the Company works with today. The picture details the latest products created with 100% UPRP coupled with Milliken’s additives.